Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine of Refrigeration Cooled Cleaners Airplane Parts Steam Tank

Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine

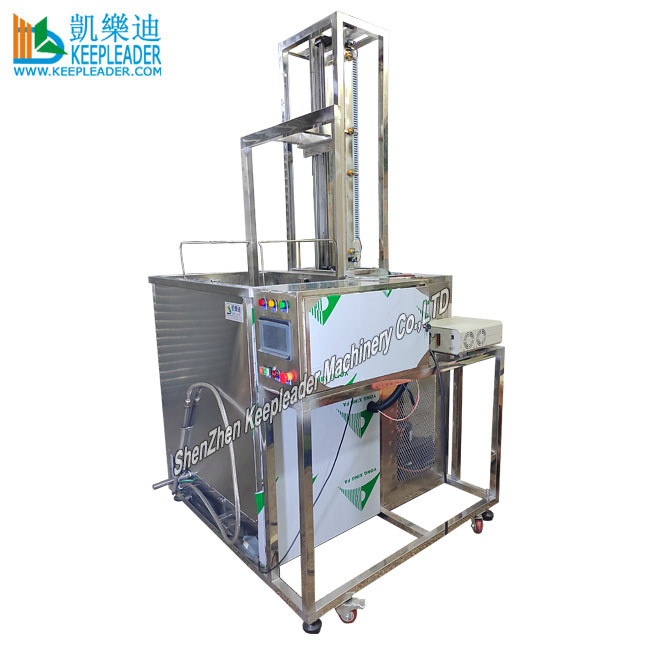

Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine employs powerful, efficient and reliable solvent vapor degreasing process that in a matter of seconds removes contaminants like machining oils, cutting fluids, waxes, flux, and many more via solvent cleaning, many industries from electronics forms to aerospace companies to metal fabricators use Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine to precision cleaning metal and machined parts, because of the comprehensive and fast cleaning capability combined with no need for rinsing drying, vapor degreasing is a valuable process of any manufacturing line, Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine utilizes non-flammable, non-hazardous, low flash-point, no-toxicity, planet-friendly, safe exposure solvents that can be recycled and reused for reduced operating costs

Machine Description

Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine

01: Application

Although water-based cleaning systems are effective to many application, some aspects of aqueous-based cleaning can make it impractical or unusable for certain cleaning application, Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine is employed for removal of petroleum based oil, grease, wax, solder flux and other stubborn solvent-soluble soils from nearly any non-porous surface, it is also very effective at precision-cleaning highly sensitive parts contaminated with dust, fingerprints, and other air-borne contaminants, Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine is commonly used to clean machined parts, electrical and electronic sub-assemblies, intricate metal and plastic component and medical device, artificial joints, lenses and a wide variety of other products prior to further processing, assembly, inspection or packaging, nearly any part can be cleaned in a Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine without concern for quality control issues like part oxidation, effective drying, and water spots, because no water is used in the process

02: Parameter

Name | Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine |

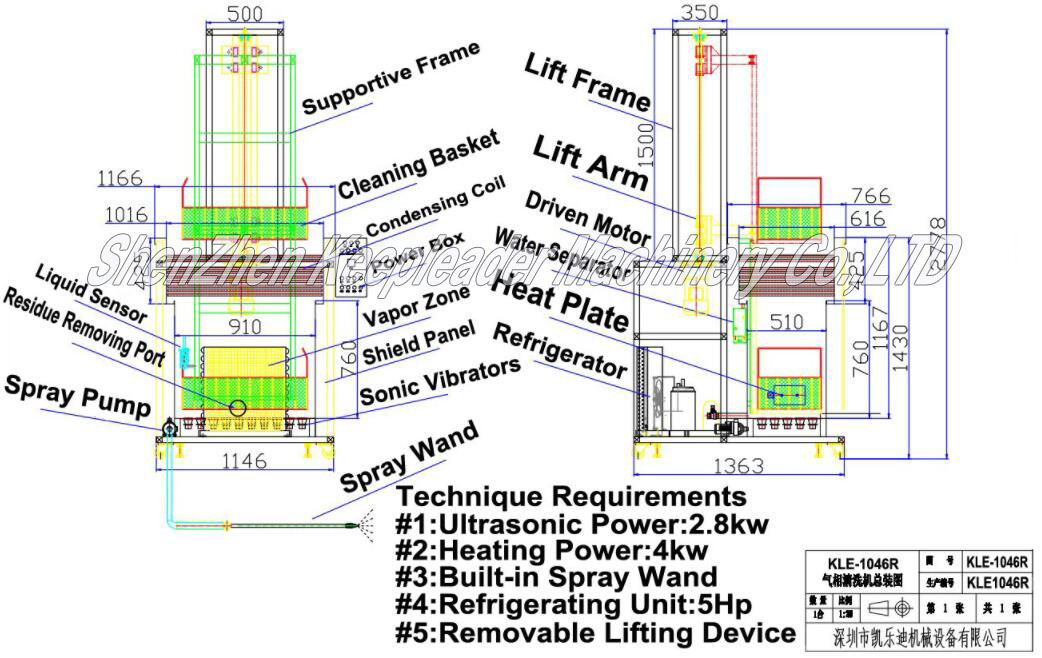

Model | KLE-1046R |

Boiling Chamber | Length:910*Width:510*Depth:760mm |

Vapor Zone | Length:910*Width:510*Depth:760mm |

Primary Heater | 4000w |

Solvent Capacity | 130~150 Liters |

Distillation Rate | 100L/h |

Ultrasonic Power | 2500w |

Spraying Power | 250w |

Lift Power | 1500w |

Ultrasonic Frequency | 28khz |

Refrigerator | 5Hp |

Electric Requirements | 380V/50HZ |

Controlling System | Programmable Logic Control with Touch Screen |

Addendum | High pressure spraying Wand. |

Packaging Dimension | 1.5*1.4*1.8m=3.78CBM |

Shipping Weight | 580kgs |

03: Salient Character

Easy maintenance reduced down-time and reduced solvent use.

Dual arrays of dual cools to enhance solvent containment.

Simple engineering means field supportability and easy-of-maintenance

Automated basket handling for part processing consistency

Customized automatic spraying wand and ultrasonic agitation

Configured primary chilling water coils and secondary refrigerated condensing coils.

Extended free-board ratio to minimize diffusion losses.

Manually operated cover to control overhead air turbulence losses.

Water separator for continuous removal of condensed atmospheric moisture

Monitoring system can identify faults, notify operator when maintenance or need service.

All stainless-steel tank, cooling coils and copper plumbing construction

Low solvent level control disables heaters if solvent level is low.

Built-in handheld distillate spray wand

Refrigerated free-board chiller system.

Automated workload elevator, single axis

Programmable Logic control with touch screen

Detailed Images

Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine takes decade years of experienced in revamping and innovation, that proves flexibility, reliability and durability in gratification, such as: reduces solvent consumption and costs: manually hermetic sealed tank lid to retain solvent, which is more efficient than machines without air-tight sealing lid; reduces solvent loss, lowers electric expense: electric pulse modulation system actuates electrical heating process in solvent boiling sump only as needed, instead of the continual heating actuation used in the less efficient machine; improved operator controls and diagnostics: compact programmable logic control coupled with high resolution, full-color touch screen; upgraded refrigeration minimizes solvent loss, increases efficiency: able to maintain a colder free-board area vs competitive models; maximizes vapor rinsing for better cleaning: distilled solvent cooler line helps reduce the process sump temperature, thereby increasing the temperature differential between components and vapor/Temperature delta; increase operator safety: exhaustive entrapped solvent vapor into the tank which can efficient reduce the risk of operator’s exposure; automatic lift can program actuation of up and down agitation; high pressure spraying wand interferes surface decontamination by jetting blast flexible whatever pro-vapor cleaning or subsequent solvent cleaning

Machine Uses

Configurated Illustration

Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine arranges all processes in one tank of boiling sump and ultrasonic rinsing sump, that also has bands of cooling coils inside just above the level of the sumps, these coils cause the vapor to return to a liquid state and fall back into he sump, the effect is like small clouds of the solvent are formed between top of the sumps and the cooling coils, as parts at room temperature are lowered through the cooling area into the vapor, the vapor from the boil sump condenses on the parts, this condensation contains the solvent that dissolves the oil on parts, and the beading action creates droplets which run across the surface of the parts and fall back into the boil sump, the parts are then continuous move to immersion, so that any blind holes or internal features are also thoroughly exposed to the solvent, finally parts are raised into the cooling coil to allow the solvent instantaneously dry and then raised through a second layer of free-board coils near the very top of the Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine that insure complete drying and the recapture of the solvent from the parts

Machine Uses

Keepleader, we commit to sharing our expertise, our team maintains and improves processes, ensuring our ability to exceed the expectations of our partners and customers, by learning more about Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine, you will start your journey of experiencing tested and approved vapor degreasing degreaser with consistent, reliable results, our advanced critical technologies come with customer support, product training and troubleshooting assistance, we offer free consultations for any Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine, that is proven to effectively remove contaminants such as surface oils, greases, solder flux and wax in industrial production field of medical, automotive, aerospace, electronics, optical and precision metal parts fabrication

Operation Guidance

Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine employs all fundamental function of ultrasonic solvent vapor degreaser, that combine cleaning and drying in one chamber, in addition, automatic lift actuate top loading and unloading with up and down agitation, handheld high pressure spraying wand free interfere jetting flush cleaning in enhancing temperature delta to improving condensing performance as long as possible, digital data acquisition, setting and monitoring is accessible via programmable logic control coupled with high revolution touch screen, we accept specified filtering circulation device to timely remove the settled residues/particulates/sludge

Contact Us

Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine comes in a variety of configurations depends customer application, we can size a vapor degreasing machine to fit not only your parts, but also you cycle time and production requirements, with contemporary solvents it is essential to size the vapor degreaser properly to ensure maximum solvent recapture through distillation cycle chilling coils, for expertise help with your precision cleaning application, look to best technology, let us assist you on tailoring the best Vapor Spray Degreasers Solvent Degreasing Ultrasonic Cleaning Machine, contact us today to obtain a free proposal

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader