Circular Plastic Welders Plastic Spin Welding Machine of Round Thermoplastic PP Filter Joint Rotary_Frictional Sealing Equipment

Circular Plastic Welders Plastic Spin Welding Machine

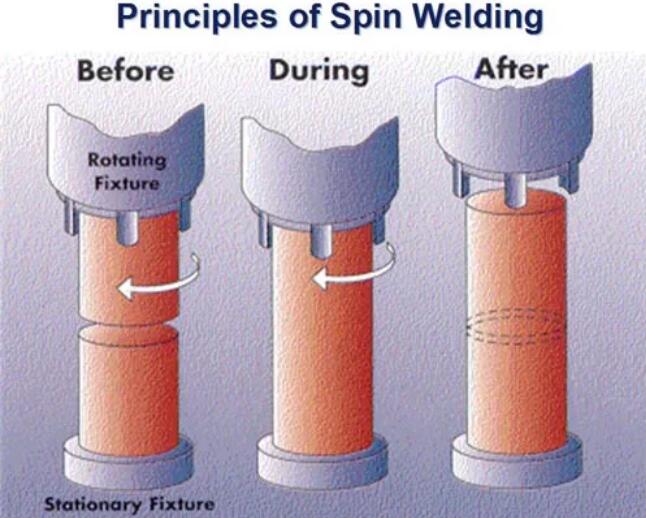

Circular Plastic Welders Plastic Spin Welding Machine also known as rotational frictional welding, that is used for fusing thermoplastic parts with a circular or cylindrical shape, this plastic assembling welder technique involves spinning one components against another at a high speed, as one of the parts rotates, the second is held stationary, frictional heat is generated, causing the joint interface to melt, the two surface are hold together under pressure until they fuse and form a strong welder at controllable vertical axis pressure applied

Machine Description

Circular Plastic Welders Plastic Spin Welding Machine

01: Application

Circular Plastic Welders Plastic Spin Welding Machine, also referred to as rotary friction welding, is the joining technology of choice when assembling spherically or cylindrical shaped thermoplastic parts, in Circular Plastic Welders Plastic Spin Welding Machine, one part, which a circular cross-section at the weld interface, is rapidly spun against its mating part which is held stationary in nesting fixture, the resulting heat that is generated by the combination of spinning action and friction brings the plastic material to its melt point and fuses the two parts together, producing a strong and impervious seal, hermetic seals are also attainable depending upon the materials used and the weld joint configuration, while Circular Plastic Welders Plastic Spin Welding Machine works with all thermoplastics and can accommodate virtually any diameter part, it is particularly suited for crystalline resins such PP,PE and Nylon in industrial assembling field, such as automobile: fuel filters, air filters, deputy air pumps, auto and Motorcycle filter, RO water purifier filter, water jug and round work-pieces; commodities: filter/cup welding, water filter/medical filter oil and any other circular/tubular shape plastic parts welding to get water-proof and air-tight welding effect; toys: stroller wheel set. Spherical/cylindrical cross-sectional joint: parts made of PP, PVC, PET and etc.

02: Parameter

Name | |

Model | KLP-1500 |

Power | 1500W |

Voltage | 110V,60HZ;220V,50HZ |

Usage | Cylindrical Plastic Assembly Joint |

Melting Type | Spinning Inertial Resistance |

Rotation Cycle | 1600 |

Driven Mode | Pneumatic Press |

Welding Delay Time | 1~99s / Adjustable |

Holding Time | 1~99s / Adjustable |

Pressure | 0.5MPa |

Cylinder | 63*75 |

Working Mode | Screw Down |

Work Itinerary | 750mm |

Pressurization Method | Pneumatic Drive |

Rotation Control | Brake Clutch |

Operation Version | English And Chinese |

Welding Area | Spherical Interface within:300MM |

Productivity | 5~10pcs Per Minute |

Dimension | 900*700*1900mm |

Packaging Dimension | 1150*900*2150mm |

Weight | 380kgs |

02: Spin welding highlights

Ability to melt significant amount of material at the joint interface.

Accommodate any diameter with proper joint interface torque and RPM.

Hermetically seals various application with strong strength.

Suitable for different thermoplastic including PP, PE, Nylon

Easy process that does not require much technical expertise.

Cost efficiency without using any consumable materials and adhesives.

Minimal risk of hat damage to the surrounding plastic parts

Ability to weld parts with a circular joint that are not easily welded by ultrasonic.

Relatively fast cycle times when compared with other methods.

No consumables, fumes or emissions and heat confined to weld interface.

Easily automated, quick-change tooling, low maintenance and low power consumption

Requires less velocity is better for engineering resins.

04: Salient Character

High efficiency, wide scope of application

Heavy structure for stale operation

Large color touch screen with intuitive menu structure

150mm stroke for greater versatility and easier part load and unload

Integrated design eliminates cables and make installation more compact.

Programmable Logic Control with touch screen and multiple languages

Four Auxiliary casters facilitate the movement of the machine.

Circular Plastic Welders Plastic Spin Welding Machine

Detailed Images

Circular Plastic Welders Plastic Spin Welding Machine is used to joint two plastic parts spherical or cylindrical in shape, frictional heat is generated at the mating surface by spinning one part (upper) against a holding part (lower), this process joints thermoplastic with a bond stronger that the parent material, Circular Plastic Welders Plastic Spin Welding Machine is fast, and works with large and small diameter parts, it is even reliable across a wide range of thermoplastic resins with sin welding, hermetically sealed joints are possible

Machine Uses

Circular Plastic Welders Plastic Spin Welding Machine takes quick bonding process for thermoplastic parts of spherical, cylindrical and tubular shape, such as floater, pain tank, spherical toy, PP thermos cup, oil filter, spray connector, thermos bottle interior and etc.

Tech Illustration

Circular Plastic Welders Plastic Spin Welding Machine exerts reliable and robust bonding assembling seals at a fast cycle time, its operation schedule proofs simplicity, the fundamental model usually includes these arrangements: step1: the two thermoplastic parts to be welded are loaded into the machine, typically one into the spin tool, and the other into a stationary supportive nest called a fixture; step2: after a cycle is initiated, the spin tool descends toward the fixture while simultaneously accelerating to programmed weld spin speed; step3: after the parts come into contact with each other, the tool continue to spin at a constant speed while the press forces the parts together, causing the interface to melt, the spinning stops once he programmed condition for ending the weld is met, such as reaching the programmed part collapse distance; step4: once the spinning stop, the hold phase follows, typically consisting of dynamic hold and static hold, during the dynamic hold, the press is advanced t to further collapse the parts while the plastic material is still molten, during static hold, the press position is maintained while the material cools and solidifies; setp5: the spin tool retracts, the two plastic parts are now joined as if molded together and are removed fro the machine as one assembly

Contact Us

Our knowledgeable applications team regularly provides joint design recommendations, material compatibility guidelines, detailed application feasibility reports and troubleshooting expertise, keepleader. We offer Circular Plastic Welders Plastic Spin Welding Machine and its technology that is reliable, efficient and controllable, and back it with unparalleled service and support.

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader