Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine of Gravure Ceramic_Stainless Steel Flexomaid Roll Degreasing Device

Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine

Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine is fully automated for roll and sleeves maintenance, individually designed to deep clean anilox rolls, sleeves or gravure cylinder of all sizes, this ultrasonic cleaner will help you reduce set-up times, minimize press downtime, increase the lifetime of rolls and optimize printing quality, Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine is a perfect solution for daily washing and maintenance of the anilox rolls, the short and gentle cleaning process leaves the rolls perfectly clean and ready for use without causing any wear or tear to the roll, Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine has been designed to work all types of ink, filtering circulation reservoir is optional function to build-in that allows the re-use the liquid and avoid secondary contamination

Machine Description

Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine

01: Application

Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine is fully automated decontaminated equipment, that employs mechanical agitation integrated chemical removing absorption to efficiently complete restoration or maintenance of anilox roller, sleeves in ink printing, individually designed to deep clean anilox rolls, sleeves or gravure cylinders of all sizes, they reduce set-up times, minimize press downtime, increase the lifetime of the rolls and optimize printing quality.

Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine is perfect solution for daily washing and maintenance of the anilox rollers, short and gentle cleaning process leaves the anilox rollers perfectly clean and ready for use in minutes without causing any wear and tear to the rollers, ceramic anilox rollers cannot be properly cleaned with conventional mechanical methods, the ceramic cell cavities are far smaller than even the finest brush bristles, although blast systems can clean coarse anilox rollers, only Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine can thoroughly can safely clean the fine count anilox rollers being used today, ultrasonic anilox roller cleaning machines have been designed to work with all types of ink, the water consumption is very low and the appropriate cleaning chemical works in conjunction with the machine to remove ink and other contaminants from the anilox roller

Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine is one of the latest and advanced technology to safely remove the contaminants from the rollers without causing and damage and are economical as well, the cleaning process releases the energy of millions of bubbles that implode by quickly eliminating all type of waste and consuming few energy resources.

02: Parameter

Name | Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine |

Model | KLE-1030A |

Ultrasonic Power | 1600W |

Ultrasonic Frequency | 40KHZ |

Heating Power | 2000W |

Tank Internal Size | Within 1450*450*250MM |

Loading Length | 1450MM |

Cleaning Efficiency | Fit 4 rollers at one Time. |

Power Supply | 110V/220V 50HZ/60HZ |

Tank Capacity | 100~150 Liters |

Temperature Control | 30~60 Celsius Degree |

Cleaning Time | 1s~99h |

Tanks Material | Stainless Steel, SUS304, and 316L |

Dimension | 1850*550*600MM |

Weight | 328kgs |

03: Salient Character

Safety module and emergency stop

No acids or other aggressive chemicals

No direct contact with cleaning tools

Without suffering erosion by abrasion

Without high local temperature

Hermetic Tanks lid with magnetic Rod

Great saving in ink consumption

Exclusive system of continuous agitating rotation

Optimized designs for low power consumption

No production rejects due to printing defects

Four anilox roller simultaneous cleaning in one cycle process

Gratify all kind of anilox roller made of ceramic or metal.

100% volume recovery at all line depths after each wash

Higher ultrasonic frequency integrates controlled power intensity to protect the rolls.

Digital ultrasonic generator to generate scalable and reliable ultrasonic energy.

Cleaning in record time without need for an operator during the process.

Manufactured in high thickness of 304/316 stainless steel for maximum durability.

Superior thermal-acoustic insulation based on closed cell elastomer.

Rotation speed of agitation is adjustable with digital controller.

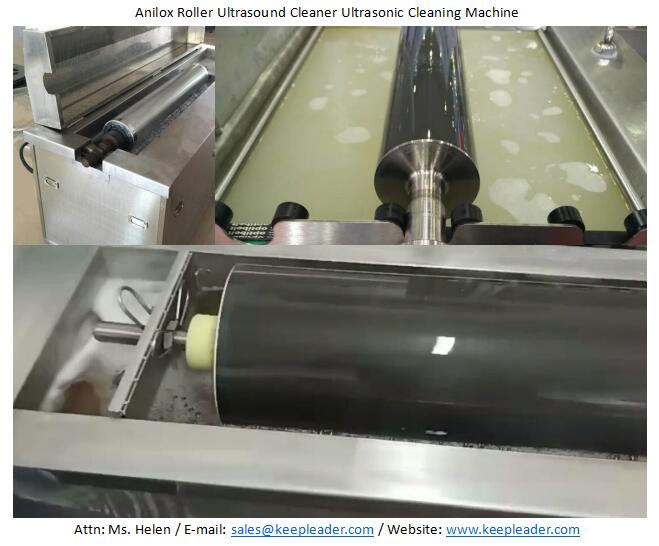

Detailed Images

Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine gains its salient characters to pioneer gratification, such as all made of stainless steel; low liquid level protection; digital temperature controller, auto-reset digital cycle timer; heavy duty cylinder rotation mechanism; safer level of ultrasonic frequency: 40khz or upper; modified power generator: now external, interchangeable and easily replacement; safer heating system: increased reliability with fixed thermostat settings and low-level automatic shutoff; customized size; more complete cleaning: of all anilox rolls from lower-line count to even the highest line-count rolls; more complete recovery: of full cell volume of anilox rolls; easier maintenance: easier replacement of routine maintenance parts

Machine Uses

Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine takes simplicity in operation, the anilox roll is partially immersed to the ultrasonic bath and located to the rotary mechanism, the tank is equipped with clamping device able to adjust different lengths of printing rolls, turning of the roll is performed by sophisticated traction system, temperature f cleaning solution is from 60~70 Celsius degree, completed anilox rolls can be rinsed by water gun over the ultrasonic tank so no dirt neither detergent is transferred to rinsing tank, rinsing operation with pure DI water to wash all the release dirt, anilox roll is located in the rinsing tank to the identical turning system as in ultrasonic tank, rinsing is made by pure DI Water produced by osmosis plant, osmosis plant s optional part of the machine, after rinsing, the operator dries printing by the air gun, that is another optional configuration

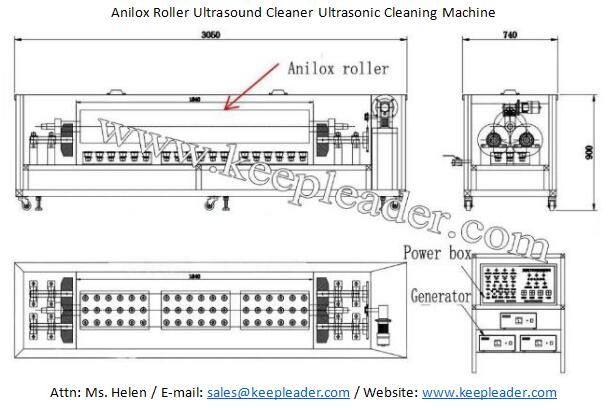

Schematic Diagram

Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine is extremely efficient at removing contaminants of anilox rollers when the optimal chemistry, cleaning cycle and temperature are used. Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine employs cavitation bubbles induced by high frequency pressure wave to agitate a liquid, the agitation produced high forces on contamination adhering to gravure wall of anilox roller, this action also penetrates roots of finest-line count rolls. In an Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine, the anilox roller to be cleaned is placed in chamber containing a suitable solution, an ultrasound generating transducer built into the chamber, produces ultrasonic waves in the fluid by changing size in concert with an electrical signal oscillating at ultrasonic frequency, this creates compression waves in the liquid of the tank which tear the liquid apart, leaving behind millions of microscopic voids or partial vacuum bubbles, these cavitation bubbles collapse with enormous energy, they are so small they they do no more that clean and remove ink clogged anilox rollers, in addition, rotary mechanism combines with ultrasonic agitation to apply reliable and consistent microscopic rubbing process. For Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine to be effective, the chemistry, temperature and cycle time must be right, this is our considered with digital control in precision control for flexographic printers in the engraved rollers and sleeves.

Contact Us

KEEPLEADER, we offer a wide range of ultrasonic cleaning system such as single tank ultrasonic cleaning machine, multi stage aqueous and solvent ultrasonic cleaners, we also offer options of filtration system, oil skimmers, mist collectors, air knives, anti-rust dips, automatic lifting device, rotary agitation mechanism in conjunction with our cleaning machines, the quality of our products has helped us secure a dominant position in our customer’s mind making us one of the most preferred supplier which new is synonym with ultrasonic, with our expertise and an undeviating urge to satisfy clients, we have established a standard in attaining maximum customer satisfaction, for our Anilox Roller Ultrasound Cleaner Ultrasonic Cleaning Machine, we available customize the tank size, function as your request, that request your specification: let us know how many aniloxes you need washing per time? What is the length is your anilox? What the diameter of anilox?

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader