Cable ID Printer Wire Marking Hot Stamping Press Machine of Electric Wires Codes Markers Hot Foil Stamp Printing Engraving Coder

Cable ID Printer Wire Marking Hot Stamping Press Machine

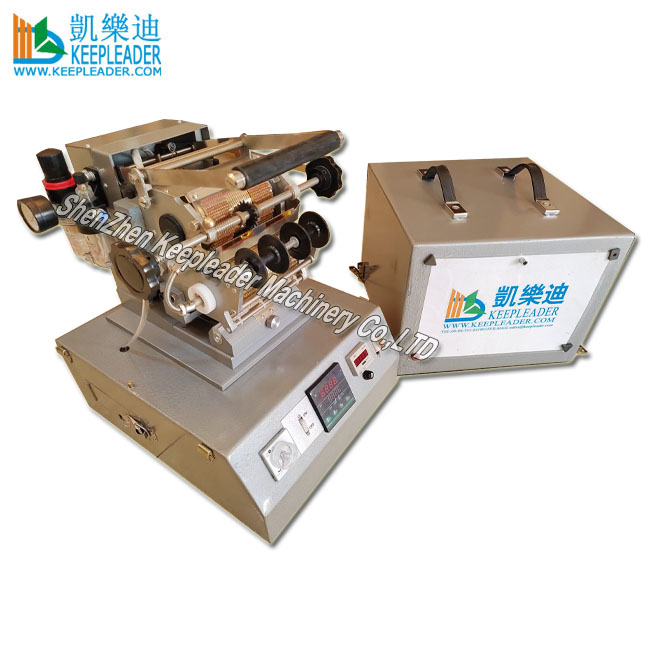

Cable ID Printer Wire Marking Hot Stamping Press Machine create debossing coding prints on insulation jacket of wire/cable/sleeve/tube by pressing a heated rotary character discs and pigment on it, this pressed character deforms the insulation sheath and causes engravings, while the pigment adheres to the insulated plastic due to heat. The pressing process is conducted by either an pneumatic cylinder, motorized driver or manual lever, the printable materials include molded products, such as bundling hands, control cables, and coated electric wires, plastic tubes, shrink sleeves, furthermore, changing he pigment color in such a Cable ID Printer Wire Marking Hot Stamping Press Machine can be easily accomplished by replacing the marking foils, moreover, no drying time is required, since liquid ink or organic solvents are not used in this process

Machine Description

Cable ID Printer Wire Marking Hot Stamping Press Machine

01: Application

Cable ID Printer Wire Marking Hot Stamping Press Machine is designed for the economical and high quality marking of wires, cable, sleeve, and tubes, the combination of characters and character size can be selected freely within the specific range, the Cable ID Printer Wire Marking Hot Stamping Press Machine is suitable for marking wire insulation sheath made of thermoplastic, during the process the preheated character wheels imprint the precision-engraved characters by pressing the pigmented marking foils into the wire/cable’s insulated surface in radius spectrum, the concave form of the characters is exactly matched to the diameter of the processed wire/cable jacket. The precise adjusting operation for the stamping pressure, and time and the marking temperature allow to recall every result.

02: Parameter

Name | |

Model | KLS-11D |

Heating Power | 500w |

Power Supply | 220v,50hzSingle Phase,3wries of 1 Live Wire,1 neutral Wire,1earth Wire |

Stamping Actuator | Pneumatic or specified. |

Qty of Rotary Discs | Within qty:38 |

Raw Material Diameter | 1.5mm!15mm |

Characters Per Wheel | Letters: A~Z; Numbers:0~9;-/。 Blank |

Character qty Per Wheel | 40 |

Marking Pressure | 0~6 Bar |

Marking time | 1.0~3.0s |

Marking Temperature | 0~205 Celsius Degree |

Type Style | Radius Character Only |

Type Size of Horizontal | 1.2~3.0mm |

Type SIZE of Vertical | 1.2~1.6mm |

Options | Foot Pedal, Motor driven, Pneumatic actuator, Manual Lever, or interface cable in-line operation. |

Marking Foil | PVC Foil or Teflon Foil |

Pigment Foil Color | Black, White (Other Color upon request) |

CE certification | Fully complied with all CE and EMC equipment guideline, relative to mechanical and electrical safety and electromagnetic compatibility |

NB | KEEPLEADER recommends that wire samples be submitted in cases where there is doubt as to the processing capabilities of a particular machine. |

03: Salient Characters

Wide carriage for end marking applications.

Stroke adjustments to ensure maximum production rata basing on wire sizes.

Large selection of character size and foils width, and colors

Foil roll rewinding system supports quick pigment roll changeover.

Standard V-block wire guide allows marking cable up to 15mm outer diameters.

Closed loop integral temperature controller for continuous temperature applied.

Capable for printing heat-shrink or PVC sleeve insulated cable, wires and plastic tubes.

Long-lasing marking obtainable with simple operations.

Identification solution for variety of applications

Contact structure and robust construction for qualified longevity.

Easy-dial wheels or individual type and blocks

Interface with other wire processors, likely meter cutter, peeling device and others.

Pneumatic powered actuator is suitable for large volume markings.

Built for reliability: enabling to maintain high speed cable marking procedure.

Highest code quality: robust and legible marking to avoid e weak imprint.

Range of ink colors: black, white, or other specified pigment to gratify substrate colors.

Detailed Images

Cable ID Printer Wire Marking Hot Stamping Press Machine is the oldest and most inexpensive method for wire identification, this method produces very durable and legible markings and can be used on both soft and hard insulation, including Teflon, as wire is manually or automatically pulled through a wire guide, a pigment foils is placed between the wire insulation and heated character wheels, a pneumatic cylinder then presses the character wheel against the pigment foil, which consists of backing and a ink layers that imprints engraved characters on the wire insulation, producing the best quality mark requires the correct foil, wheel temperature, pressure and dwell time, pressure is a measure of how hard the character wheel press against the wire, dwell time is the length of time that character wheels contact the wire, Cable ID Printer Wire Marking Hot Stamping Press Machine has two important limitation, the first is it creates an embossing imprint that cold possibly affect the integrity of thin insulation, another is the slow production rate, which keeps it fro being used for application involving large amount of wire, but, flexibility and inexpensive performance results in prevalent yields, in addition, Cable ID Printer Wire Marking Hot Stamping Press Machine can interface with automatic cutting, stripping and terminating machines for a whole cycle production in wire products making

Machine Uses

Cable ID Printer Wire Marking Hot Stamping Press Machine employs electric heat rotary character discs and thermal marking foil to imprint identifying codes to the insulation surface of wire/cable, the wire is fed through a V-block guide or anvil and the guide assembly lifts up to contact the heated character surface with the foil sandwiched between the character and wire, the separate marking characters are arranged in the desired number sequence and engraved around the rotary discs, in the case of a wheel character of Cable ID Printer Wire Marking Hot Stamping Press Machine, each wheel represents one character and includes the characters generally used (0~9,A~Z, blank and special marks, right and left arrow and hyphen), wheel characters are quicker to change over and lend themselves better to manual or automatic processing, actuation is by lever or foot pedal or manual (offline) processing and integrated into a semi or fully automated solution with actuation controlled by the automation system, Cable ID Printer Wire Marking Hot Stamping Press Machine is less prone to environmental condition that can affect affect the adhesion of a wire label, some industries specify other marking approaches as the mark is imprinted to the surface of the wire using heat and there are concerns about potential damage to be insulation, bu the cycle time is limited and the heat applied is localized so this processing method is acceptable for the majority of application, end marking (same or different number on opposing ends of the wire) and continuous (along the length of the wire at a fixed distance) are normal processing types, continuous marking does slow down a semi or fully automated wire processing machine as the wire feed must stop during the stamping process, the number of marks and distance between marks affects processing speed, the type of thermal marking foil used, the temperature of the type and impression time are critical factors for a Cable ID Printer Wire Marking Hot Stamping Press Machine, the insulation type and wall thickness determine the foil, temperature and cycle time, marking foil normally comes in rolls and is white and black

Contact Us

Cable ID Printer Wire Marking Hot Stamping Press Machine is one of the most cost effective, permanent ways to identify your wires and cables, over decades of year, we’ve perfected the process which involves a delicate balance of heat, pressure and pigment foil, we take bespoke construction for versatile wire marking application, Cable ID Printer Wire Marking Hot Stamping Press Machine allows for marking on a large variety of tubing, sleeving, identification markers plates, ID cable ties, we remain available for any clarification, for convenience, favor he end-user provide us with their photo of expected result, believe that our experienced team take capability of offering a reliable solution at affordable price for your wire marking process

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader