Solvent Degreaser Equipment Degreasing Machine of Aviation Accessories Decontamination Oil Removing Distillation Cleaning System

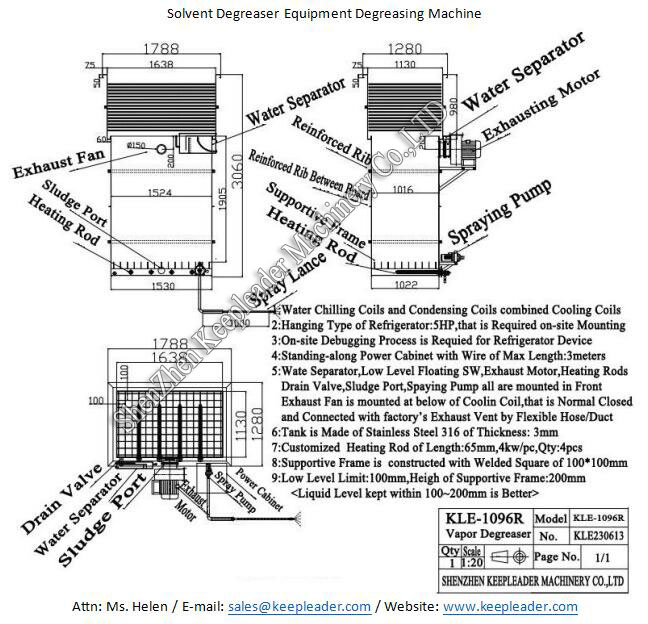

Solvent Degreaser Equipment Degreasing Machine

Solvent Degreaser Equipment Degreasing Machine employs vaporized solvent in place of aqueous solutions to clean various contaminants from objective parts, typically, the parts are placed in baskets or suspended and lowered into the degreasing tank via a crane, hoist, lift, elevator or other automated material dunking system, the parts are either submerged in the solvent or suspended above the solvent in the vapor zone where the solvent can condense on the parts allowing the soils to dissolve away, options for cleaning including ultrasonic agitation or high pressure spraying system for importing additional mechanical energy to the process, solvent distillation and filter system can dramatically extend the life of solvents, helping cleanliness levels and keeping cost low, some advantages of Solvent Degreaser Equipment Degreasing Machine over aqueous-based processes include 100% dry parts immediately on removal from the degreaser and the ability to clean tough soils and heavy oils at low temperature

Machine Description

Solvent Degreaser Equipment Degreasing Machine

01: Introduction

Solvent Degreaser Equipment Degreasing Machine is our single tank ultrasonic vapor degreaser with high frequency spraying wand, and exhausting draft fan, that uses boiling solvent, rather than water, for fast precision cleaning and removal of true oils from aircraft parts or other industrial metal parts, typically for helicopter Landing Gear assembly, Solvent Degreaser Equipment Degreasing Machine applies the principles of distillation and condensation to achieve high-quality cleaning and quick drying in a cycle process at comparative low pricing, Solvent Degreaser Equipment Degreasing Machine has been around for a long time, but that doesn’t mean they are all created equal, best technology offers the highest quality vapor degreasing equipment for seal in the industry, the significant advancements in cleaning solvent fluids have brought increased solvent costs, therefore, vapor degreaser solvent recapture and vapor degreasing distillation have never been more important, ensuring the proper boiling heat capacity balanced with chilling capacity and free-board is a must for today’s vapor degreaser, keepleader, we are experienced in proper Solvent Degreaser Equipment Degreasing Machine sizing and the latest vapor degreaser solvent used in them, in addition, high pressure spraying wand, filter circulation reservoir, automatic dunk lift, and primary water chilling coils coupled with second sub-zero reciprocation refrigerating system and ultrasonic agitation boiling, immersible rinsing in separated sumps as optional addendum are integrated into this Solvent Degreaser Equipment Degreasing Machine

02: Parameter

Name | |

Model | KLE-1096R |

Maximum Loading Size | 1524*1016*1905MM(Length*Width*Depth) |

Maximum Loading Weight | 700kgs |

Cooling Blanket Size | 1624*1116*980mm |

Supportive Frame Net Size | 100*100mm |

Height of Supportive Frame | 200mm |

Low Liquid Level | 100mm |

Liquid Level Scale | 100~200mm |

Power Supply | Phase Voltage: 220V, Line Voltage:380V,3 Phase,5 wires |

Heating Power | 16000w (Heating Rod of 4kw/pc*4pcs) |

Refrigerator Power | 5Hp |

Spraying Wand Power | 2000w |

Exhausting Fan | 1000w |

Solvent Capacity | 200~300L |

Distillation Rate | 100L/H |

Material | All Stainless Steel, thickness 3mm |

Overall Dimension | 1788*1280*3060mm |

Packaging Volume | 12.004CBM |

Weight | 1238kgs |

03: Salient Character

Big loading size to gratify large geometric metal parts vapor degreasing

All made of stainless steel of thickness: 3mm

Reinforced section for seam combination to improve standing gravity

Net welded supportive frame can apply maximum 700kgs loading

Exhausting fan is built-in for adjustable solvent intensity control

Liquid low level control to avoid dry heating and empty condensing process

High pressure spraying wand is freely arranged before or after vapor degreasing process

Manual tank lip to contain the solvent vapor to decrease the emission

Standing-along power cabinet to gratify flexibility of on-site movement

Cooling Coils consisted of primary chilling water coils and second sub-zero condensing coils

Built-in oil-water separator to continuous drain out condensed humidity

All functional configurations in one tank to save the footprint

Ultrasonic immersible penetration at the beneath of tank is optional

Extended free-board ratio to minimize diffusion losses

Copper/brass plumbings and stainless steel condensing coils

Indicator of vapor-up to advise operator when the system is ready to process parts

High vapor temp sensor to transmit signals of halt heaters in case of solvent replacement is needed

04: Buying Guidance

The reliability of Solvent Degreaser Equipment Degreasing Machine requests proper configuration, operation and maintenance, in addition to the hardware issues, the proper solvent selection requires careful analysis, and that selection depends on the contamination being removed, when analyzing the application, always define the impurities first, then select the chemistry that removes those impurities, as well as the Solvent Degreaser Equipment Degreasing Machine that uses the chosen solvent properly

There is an old saying in the industry about parts cleaning “like dissolve like” hence, the best way to remove contamination is to use a cleaning fluid that is chemically similar to the contaminant itself, contaminants are typically identified as polar (inorganic), non-polar (organic) or particulate.

Polar or inorganic contaminants:are soluble in water, in machining, polar soils include salts, soaps, emulsion residue, graphite, and anti-wear and extreme-pressure additives, they also include oxidation, such as rust and tarnish, heat scale, smuts, carbonaceous and metallic components, aqueous cleaners are good as removing these contaminants since the water-based detergents and surfactant emulsify and encapsulate contaminants so they can be washes away.

Non-polar or organic soils are solvent soluble, therefore, therefore, using a solvent-based cleaning fluid is the best choice, typical non-polar or organic contaminants include hologenated, oxygenated and hydrocarbon soils like machining and stamping oils, thick grease, wax, baked-on resins, corrosion protection agents and esters, they also include things like drawing compounds, spinning lubricants, buffing compounds and fingerprint, solvent-based cleaning is ideal for these types of soils, since the solvent dissolve the contaminants and washes them away, Solvent Degreaser Equipment Degreasing Machine adopts vaporized solvent to clean in condensation and distillation

Particulate include insoluble contaminants like metal chips, shavings, dust, dirt, soot, surfactant, stearates, fibers, polishing pastes and any other contaminant that will not dissolve in water or solvent-based cleaning fluids, instead of being solubilized or dissolved, the particulate is displaced or lifted off the components and then washes away, the cleaning fluid gets under the particulate, dissipates the static holding it to the part and floats it off the surface, displacement cleaning is used in both aqueous and solvent-based cleaning methods

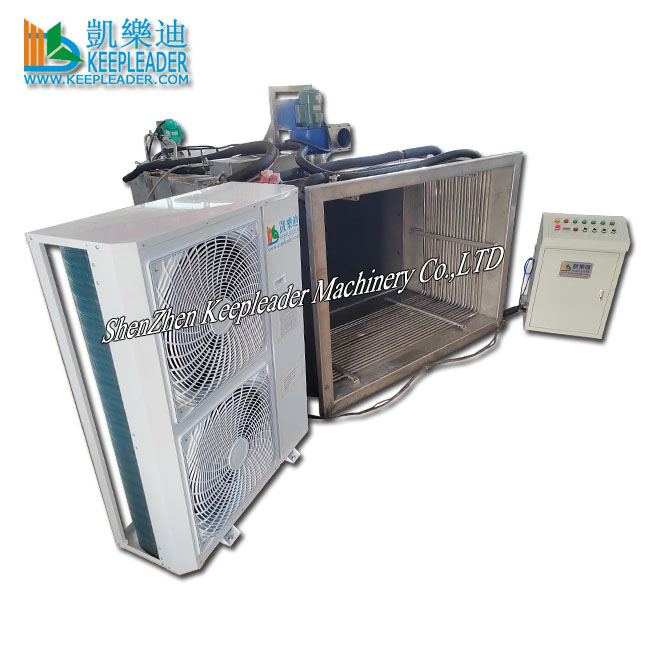

Detailed Image

Solvent Degreaser Equipment Degreasing Machine integrates solvent boiling and solvent rinsing immersion in one tank, once boiling, the solvent produces a clear, dense vapor that rises through the degreasing tank, displacing the air in the degreaser, eventually the vapors rise up and reach the lower set of cold coils called the primary condensing coils, these coils chill the solvent vapors and condense the solvent back into its liquid state, this liquid drips into a condensate through that is under the primary condensing coils and around the interior circumference of the degreasing tank, there it routes through a water separator decanting any water that may have condensed on the condensing coils and removing it from the solvent, at this point, the distilled solvent is directed back into the rinse sump from the water separator, since the rinse sump is already filled with clean solvent, the addition of clean, newly distilled solvent will cause the sump to overflow into to boil sump, completing the distillation cycle, however, Solvent Degreaser Equipment Degreasing Machine shares the same sump between boiling and rinsing, hence, no overflow procedure happen, the addition of this fresh, pure solvent maintains a consistently clean rinse sump, it also allows contamination and particulate to be washed back into the boil sump and concentrated there

Illustrated Configuration

Solvent Degreaser Equipment Degreasing Machine is an industrial cleaning process for precision parts, it employs solvent immersion, combined with solvent rinsing and drying to remove all types of contaminants, this includes oil, grease, wax and particulate, the concept is very simple, a Solvent Degreaser Equipment Degreasing Machine is a closed-loop system consisting of a top-loading steel vessel composed of boiling sump and cooling blanket, the solvent is vaporized with electric heating, cooling coils contain the vapor to avoid emission, that apply a vapor cloud that rise to meet two sets of cooling coils, these cooling coils cause the vapors to condense and return to their liquid state, this liquid then channels back to the boiling sump; a hoist lowers a basket containing the contaminated parts through the vapors and into the boil sump first, where the solvent immersion rinsing is achieved simultaneously for all-in-tank design, that has been condensed from the vapors, this process is easily programmable and allows for excellent process control and repeat-ability, the parts come out clean, dry and immediately ready for packaging or further processing, it has been in the past decade or so hat leading companies have commercialized new, environmentally-acceptable cleaning chemical suitable for vapor degreasing, this means that the speed, convenience, and energy saving of this proven technology is easily available to engineers everywhere

Machine Uses

Solvent Degreaser Equipment Degreasing Machine offers a number of advantages, such as: high effective cleaning: vapor degreasers and solvents they use are capable of easily removing almost any kind of contamination, including waxes, heavy greases, and oils of varying viscosity; versatile cleaning: vapor degreasers and the special solvents they use are able to easily penetrate and manoeuvre around even the tiniest of parts, even those with extremely close clearances, resulting in flawlessly clean contours and components; speedy cleaning: since vapor degreasers have very short cleaning cycles, even a modest batch machine can usually outperform an in-line water cleaning system that costs two or three times as much; No entrapment: because the solvents evaporate so quickly, it is simple to remove the vapors from designs that contain complex shapes, deep holes, blind via. And other elements in which slow-drying solvents would either be unable to clean o could become trapped, because of this, costs are reduced while quality is maintained; no water spots: vapor degreasers are ideal for cleaning optics and other super-critical applications, because they never leave behind any water spots, whereas water frequently leaves behind unacceptable water spots; broad material compatibility: since there is no high pressure spraying involved, the temperatures are kept low, and the cleaning cycles are kept to a minimum, solvents and vapor degreasers are excellent chooses for use with the majority of the components; planet-friendly cleaning: because they only require a small amount of electricity and do not require the use of water, Solvent Degreaser Equipment Degreasing Machine is very kind to the environment; lowest cost-per-part-cleaned: both the purchase and use of Solvent Degreaser Equipment Degreasing Machine are very economical options, a contemporary vapor degreaser can reduce the amount of solvent needed to just a few pennies or dollars per day

Contact Us

Production machining is a diverse manufacturing sector requiring a wide variety of cleaning needs, the contaminant will also vary from machining oils, metal fines and marking inks to greases, fingerprints and waxes, to successfully remove the contaminant, use specific cleaning fluids to displace soils and leave parts clean and dry, the cleaning method will always depend on an individual problem, a properly designed operated and maintained Solvent Degreaser Equipment Degreasing Machine is the very best and least-expensive cleaning choice for most industrial application, however, there are a lot of factors that need to be considered to achieve the best result, understanding the specific contamination and the part and time limitation will help in deciding the best process to use, to ensure a method will work correctly, it is essential to test first, experience and expertise are helpful in optimizing and developing cleaning cycle that will best suit a specific job, so it is important to consult with us, keepleader, we can test and provide cleaning solution to meet requirement, contact a Solvent Degreaser Equipment Degreasing Machine expert today to receive a free proposal

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader