Servo Spin Welder Orienting Rotation Plastic Welding Machine of Round_Circular Thermoplastic Orientation Rotary Friction Welders

Servo Spin Welder Orienting Rotation Plastic Welding Machine

Servo Spin Welder Orienting Rotation Plastic Welding Machine is an electric press system utilizing servo motors to provide precise control and accuracy for welding assemblies with circular weld joints, by utilizing state of the intellectual servo programmable logic control, this Servo Spin Welder Orienting Rotation Plastic Welding Machine provides angular advertent orientation and overall assembly height consistency, controllable melting assembly mode can b enabled during the weld phase, in which the motion of the vertical axis is coordinated with that of the spin axis to match the rate of melt of the material being welded

Machine Description

Servo Spin Welder Orienting Rotation Plastic Welding Machine

01:Application

Servo Spin Welder Orienting Rotation Plastic Welding Machine belongs to solid state frictional melting assemble of thermoplastic parts with circular or cylindrical joint interface, its process is achieved in case of thermoplastic parts with rotational symmetrical joint surfaces are rubbed together under pressure in an unidirectional circular motion, normally, one half is held stationary while the other is rotated, the heat that is generated during this process melts the plastic at the interface, forming a weld upon cooling, Servo Spin Welder Orienting Rotation Plastic Welding Machine is a simple and highly energy efficient process, there is little excess heat generated, which means that cooling times are short, this makes the process well suited to automated assembly line application, strong, hermetic joints can be produced, which are frequently stronger that the parent parts, no foreign materials are introduced into the weld and no environmental considerations are necessary, as in solvent sealing or adhesive bonding, the first reported application for Servo Spin Welder Orienting Rotation Plastic Welding Machine was in the manufacture of fluid-filled compasses, where welding was carried out beneath of the surface of liquid, the process can therefore be used for sealing a liquid in a container, other applications include fuel filters, check valves, truck lights, aerosol cylinders, and floats, Servo Spin Welder Orienting Rotation Plastic Welding Machine is also used for assembling structural components, connecting ventilation pipes to blow-molded fuel tanks, and welding tops and bottoms on containers, almost all thermoplastic can be joined with axisymmetric interface whatever angular orientation or not

02: Parameter

Name | Servo Spin Welder Orienting Rotation Plastic Welding Machine |

Model | KLP-2900 |

Motor Power | 2900w |

Motor Type | Servo |

Precision | 0.1 Degree |

Velocity | 1500RPM |

Rotation Cycle | 30 adjustable |

Delay Time | 10econds adjustable |

Holding Time | 0~100 seconds adjustable |

Welding Pressure | 0.5~0.7MPa |

Torsion | 10 N*M |

Power Supply | 110V/220V, 20/60HZ |

Rotation Circles | 1~100 (adjustable) |

Delay Time | 1~99s (adjustable) |

Cooling Time | 1~99s (adjustable) |

Driven Mode | Servo Motor Activation |

Dimension | 1150*900*2150mm |

Weight | 400kgs |

03: Salient Characters

High resolution touch screen of programmable logic control for setting and operation

Programmable upper and lower limits for advanced process control

Menus available in Chinese and English version

Extra-rigid steel column with negligible defection

Programmable top of stroke position to reduce vertical stroke and cycle time

Weld by revolution, time, collapse distance or absolute distance of non orientation

Spin initiation/trigger by height with programmed delay time

High precision servo spin drive with orientation accuracy of less or more 0.1degree

Up to 150mm stroke for greater versatility and easier part load and unload

Integrated design eliminates cable and makes installation more compacts

04: Highlighted Performance of spin welding

Ability to weld parts with a circular joint that are not easily welded by ultrasonic

Relative fast cycle times when compared with other approaches

Compatible with most thermoplastic, particularly takes bonding capability for PP and PE

Ability to weld several dissimilar materials

No consumables, fumes or emissions, and low maintenance

High Strength, hermetic, airtight welds are typical

Heat solely confined to weld interface, and easy automated

Low cost, quick change tooling of manual or pneumatic clamping fixture

Low power consumption, high power, and position-based indexing possible

Require lass velocity and better for engineering resins

Easier to automate and improved process control

Automatic aligned to any specified position during 360 degree at tolerance within 1 degree

No need store energy or inertia, the servo motor can actuate spin at any position

05: Sequence of Operation

05.1:Operator loads part halves into holding fixture and driver

05.2: Operator initiates both cycle activation switches

05.3: Actuator moves driver and rotating part half (typically without rotation) into contact with the stationary fixture part half

05.4: Operator is permitted to release cycle activation switches after part to part contact is made

05.5:Servo motor spins parts at user programmed RPM for the number of user-programmed revolution (or user-programmed timer, collapse distance, or absolute distance) and terminates rotation when desired weld criteria are reached

05.6: Welded parts cool/melted plastic solidified under pressure

05.7: Actuator retracts to home position, and servo slowly rotates to user-programmed home position

05.8: Operator removes welded parts from fixture

Detailed Images

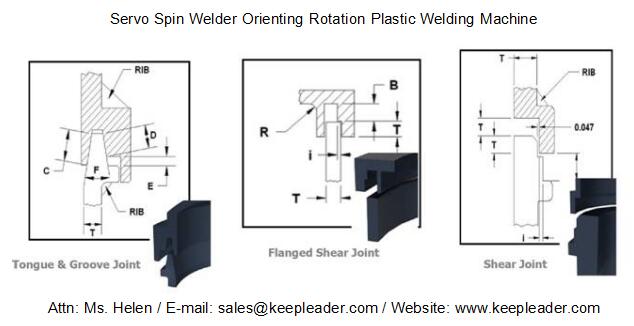

Servo Spin Welder Orienting Rotation Plastic Welding Machine produces a welded joint which, in many cases, yields a weld strength that is consistently equal to or stronger than any other area of the part, as a result, the weld area can most often be expose to the same strains and stresses as any other area of the part, Servo Spin Welder Orienting Rotation Plastic Welding Machine involves configuration and consideration in its designation of welding object and tooling sets, such as spin welding joint design: a good welding joint should has a weld area equal to or greater than a typical well section of the part, joints should also provide sufficient part-to-part alignment; Spin welding tooling sets: Driver, custom made tool used to spin the part and generate the weld, driver commonly use raised or relieved surface to engage raised or relieved drive features on the spinning art half, taped silicone drivers can also be used on parts that do not have risen or relieved drive features; holding fixture, the non-rotating part half must be held securely so that one part half does not rotate and remains alignment with the spinning part half, part details such as protrusion and lugs/ribs on the outside of the part aid greatly in preventing rotation.

Machine Uses

Servo Spin Welder Orienting Rotation Plastic Welding Machine gains prevalent application of semi-crystalline thermoplastic assembling process with circular or spherical joining interface, such as manifold valves, thermal cup, water/oil filtering cartridge, jug, barrel, and round container, Servo Spin Welder Orienting Rotation Plastic Welding Machine has prominent melting results because of #1: Perfect mastery of stopping values; #2: repeatability of the process in consistent welding strength; #3: mastery of penetration speed; #4: optimized productivity gain; #5: standing-along working status for freely arrangement of productive scenario

Tech Illustration

Servo Spin Welder Orienting Rotation Plastic Welding Machine is a process that joins circular, round thermoplastic injection-molded parts by bringing the part interface together, under pressure of servo-motor driven, with a circular, spinning motion to achieve displacement motion at sharing interface, one half is held stationary in a fixture cavity/anvil, which the other half is rotated against it under axial loading pressure, the frictional spin heat that is generated caused the part interfaces to melt and fuse together, because of flash trap slot is designed in the joints, hence, no overflow happens. However, creating a strong and hermetic seal

Contact Us

Tell us about your application when you select Servo Spin Welder Orienting Rotation Plastic Welding Machine for your round plastic half assembling production, whether you want an integrated spin welding head, a standing-along spin welder or custom automation spin welder, we have got your covered with one-stop service at competitive pricing.

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader