Flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner of Flexomaid Ceramic Rolls_Printer Heads Cleaning Machine

Flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner

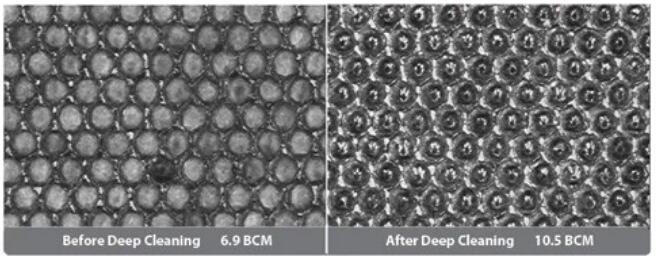

Flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner integrates automatic rotation device to agitate ultrasonic penetration in anilox roller, sleeve maintenance, its sliding actuating bridge can gratify versatility with adjustable length, flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner is a perfect solution for daily washing and maintenance of the rolls, short and gentle cleaning process leaves the rolls perfectly clean and ready for use in 30 minutes without causing any wear and tear to the screen, ceramic anilox rolls cannot be properly cleaned with conventional mechanical approaches, the ceramic cell cavities are far smaller that even the finest brush bristles, although blast systems can clean coarse anilox rolls, only ultrasonic cleaners can thoroughly and safely clean the fine count anilox rollers being used today, high frequency ultrasonic amplitude can effective penetrate deep ceramic well and complete decontamination of all types of link, the water consumption is very low and the appropriate cleaning chemical works in conjunction with the machine to remove the ink and other contaminants without any damage and are economical as well

Machine Description

Flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner

Model | KLE-1030A | KLE-1036A | KLE-1048A | KLE-1072A |

Ultrasonic Power | 1500W | 1800W | 2400W | 3600W |

Frequency | 40Khz | |||

Heating Power | 1800W | 2400 W | 2400 W | 3000W |

Tank Size | 1450*450*250 | 1650*450*250 | 2200*550*300 | 2500*550*300 |

Tank Material | 2mm thick 316L stainless steel | |||

Shell Material | stainless steel | |||

Power supply | AC100V-120V, AC220V-240V | |||

Dimension | 1850*550*600 | 2050*550*600 | 2650*65*600 | 2900*650*600 |

What’s anilox roller and how to clean it efficiently?

Cleaning the equipment and heavy duty products is a tough task that can’t be performed with simple tools. Due to the frequent use of the machine and electronic parts, deep cleaning is essential to give it proper and smooth function in every use, most of companies search for the technology, which covers the work in a easy way

Thanks to the advance developments in the field of technology and printing, that anilox rollers have gained a lot of popularity that a transfer roller. Mainly, anilox roller is a versatile tool in coating and decorative applications and right now it is being used to create prominent capacity whites and foundation coats, mainly for the stretchy packing, applying coatings, adhesives for the cold foil, coating for the images varnishes and other decorative purposes

It is a ceramic roller or an engraved metal roller mainly brought into use for the printing press to transfer the ink form the roller to the printing plate, its main purpose is to pick the ink from the roller or form any of the configurations and deliver a uniform amount of it to the robber plate for the printing process

It is mainly designed for most favorable ink release as a surface and it is laser fixed to reduce the porosity of cell wall and is strengthened by its ceramic subsurface, which benefits the printing quality, optimized cell profiles, improved consistency and more volumes of screen definition

It is mainly designed for most favorable ink release as a surface and it is laser fixed to reduce the porosity of cell wall and is strengthened by its ceramic subsurface, which benefits the printing quality, optimized cell profiles, improved consistency and more volumes of screen definition.

Used for printing task for good impression on the material

In printing task, anilox play a major role to provide the required amount of the ink to a flexo printing plate, this hard cylinder shaped roller contains millions of fine dimples referred as dells and are semi submerged in the fountain of ink to make a thick layer of it on the roll, after that, a doctor blade is applied to scrape the extra ink from the roller surface to have the measured amount of ink in the dimples

After this, the roller is rotated in contact with the printing plate on whick the ink from the cells get transferred on the material for the required impression, this provide better performance and offers cost effective solutions to the customs, after the use of this metallic roller, there is no need of any ho foil units to complete the task and face the competitive market, just select your type of roller and let it do proper work with special care

Needs proper maintenance

Due to the regular use of anilox rollers for printing work, proper maintenance is essential to give it durability and flexible use, to maintain it, ultrasonic anilox cleaner is the most efficient method to clean the anilox roller as it is a tested and proven method for cleaning most of the components which are tough to be cleaned in a normal way

The reason to use it is that, ultrasonic cleaning technique is a fast method and cleans up to 90% of the product, there is no need to let the people watch the cleaning process and handle it as it does no its own with labor saving benefits

Mainly, ultrasonic reaches to the depth of the roller and clears any residues of the ink or liquid from the holes, cervices, internal chambers, which cannot be cleaned efficiently with other device, the waves of ultrasonic go through the microscopic cell openings disturbing the cleaning liquid deep in the cavities of the cell to remove the settled and dried ink from every bottom corner of the roller to tet the best cleaning results, make use of a heated cleaning solution which is specifically formulated for the cleaning task at a certain temperature which is recommended by experts

Clean it effectively for better performance

As ultrasonic anilox roller cleaners are mainly designed for anilox rollers, proper care need to be taken to prevent any damages as ultrasonic system is specifically designed for safe and effective leaning on the metal and ceramic rollers, the ultrasonic cleaner provides a pre-determined frequency operated on its won with low voltage supply which maintains a stable distribution split from a line fluctuation which results in hot spot being shifted up and down to prevent the damage due to the concentration of the power at one point one the roller, it is quite essential to keep your anilox rollers clean to deliver more volumes of printing work which involves the interaction of multiple colors of ink as per the requirement of the customer which is must to compete in the market, it is more vital to maintain a good anilox roller which is the most effective thing to develop business and production, it is specially mentioned to use the brushes and tools which clears the minute cell in the roller in a better and safe way without damaging the sensitive parts that are most important to perform the printing work on the plate

Detailed Images

Flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner embarks decontamination into screen gravure of anilox rolls and ceramic sleeves, that increase the performance with optimal chemistry, cleaning cycle time, and temperature are used, its working principle complies with medical device precision cleaning, cavitation bubbles induced by high frequency pressure waves to agitate a liquid, the agitation produces high forces on contamination adhering to substrate like metal, plastic, glass, rubber and ceramics, this action also penetrates blind holes, cracks, and recesses like the cells engrave into an anilox roll or ceramic sleeve

In Flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner, the anilox rolls are placed in a chamber containing a suitable solution, ultrasonic transducers mounted at the beneath of chamber, that produces ultrasonic waves in the fluid by changing size in convert with an electrical signal oscillating at ultrasonic frequency, this creates compression waves in the liquid of tank which tear the liquid apart, leaving behind millions of microscopic voids or partial vacuum bubbles, these bubbles blast with enormous energy, however, they are so small, that they do not more that clean and remove surface dirt and contaminants, in addition, anilox rolls solely submerse gravure or sleeve, and rotation agitating can efficiently peel of the loosen inks this reciprocating dirt layers removing process escalates ultrasonic penetration

Buying Guides

Flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner is very effective with all types of ink used in flexography, it is also easy to install and operate, the operator solely complete loading and unloading, the machine can achieve cleaning process automatically, this ultrasonic cleaner also can integrate filter circulation reservoir to timely filter cleaning agent so it can be reused for an extended period of time, which is very economical, the system has low water consumption , investment costs are relatively low and washing machines can be easily adapted to suit the individual needs of the printing company,

Product Effects

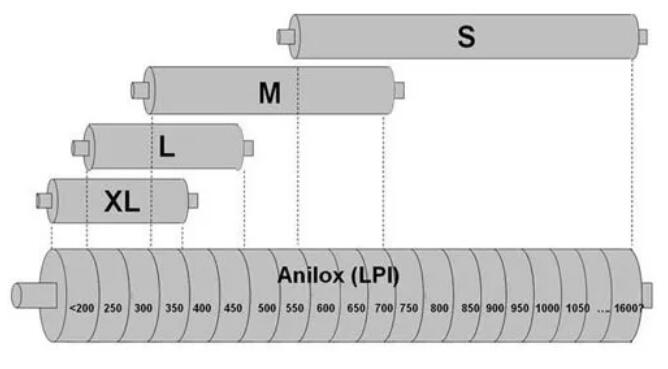

Flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner adopts ultrasonic wave energy that creates cavitation when introduced into a liquid, the cavitation is caused by pressure differentials, providing the cleaning action when anilox rolls submerse into the liquid, when using ultrasonic agitation, must be aware that excessive exposure time can cause cell damage, to monitor this, ultrasonic generator is generally controlled by times to limit exposure time and minimize damage to anilox cell, in addition, we prioritize high ultrasonic frequency 40khz or higher to avoid jeopardizing possibility, as a role, higher line screen engravings require shorter cleaning times and are more susceptible to jeopardize, as shown in the following examples

Instance1: an 800-line screen roll contains 736,000 cells per square inch (wall width is 3 microns, cell depth is 8 microns) the exposure time recommended to cleaning an 800-line screen should not exceed 3 minutes

Instance2: A 200-line screen roll contain 46,000 cells per square inch (wall width is 7 microns, cell depth is 34 microns)this lower line screen takes longer to clean, and can tolerate an exposure time of up to 20 minutes because wider walls are not as susceptible to jeopardize

The following referential data outlines exposure time recommendation for cleaning anilox rollers using Flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner

Line Screen: 360 and below: ultrasonic cleaning time: 20 mintues; Screen line:380~440: 15 minutes; line screen: 460~660: 10 minutes; Line Screen: 680~800: 3 minutes

Contact Us

Flexographic Printing Anilox Roller Gravure Washing Ultrasonic Cleaner combines ultrasonic waves and cleaning agent to thoroughly wash the anilox rollers, this anilox rolls rotates in the heated chemical agent solution (e.g: caustic soda), ultrasound waves activate a cavitation process, forming gas bubbles whose implosion on contact with the anilox surface release pressure and temperature that help dissolve and destroy contamination in anilox cells, because each machine has maximum loading length and quantities, hence, we request the end user suggest us their top limit in versatile length, kindly consult our sales representatives to gain a reliable solution at affordable price

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader