Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser of Two Tanks Chemical Vapour Steam Refrigeration Cooled Cleaner

Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser

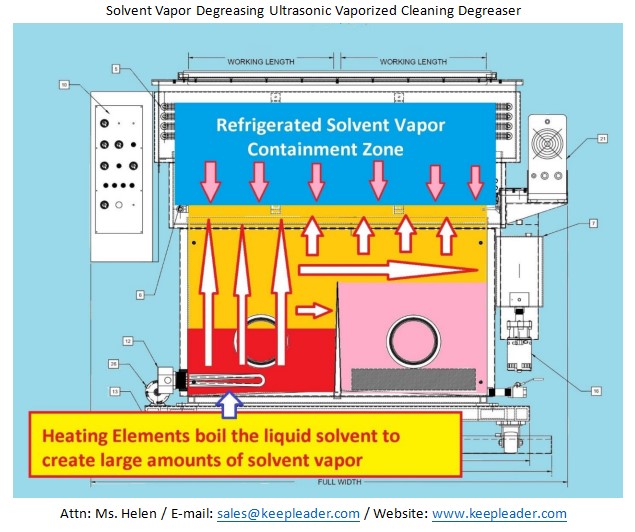

Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser works by boiling solvent to create vapor, which then condenses on the parts’ surface, the solvent dissolves stubborn soil on the parts, the solvent droplets and encapsulated soils are lifted from and then drip off the parts via gravity, to be recycled back into the boiling solvent for additional cleaning, Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser offers a number of advantages, such as: highly effective cleaning: vapor degreaser takes capability of remove almost any kind of contamination, including waxes, heavy grease, and oil of varying viscosity; versatile cleaning: vaporized vapor can penetrate any crannies and hook, even the tiniest of parts with extremely close clearance, resulting in flawless clean; speed cleaning: since vapor degreaser has very short cleaning cycle, only within several minutes, decontamination and ultimate drying can complete in a cycle; No entrapment: solvent vapors evaporate so quickly and complete condensation to form droplets and withdraw into the boiling tank in specified procedures; No water Spots: vapor degreaser is ideal for cleaning optics and other super-critical applications, because they never leave behind any water spots; Broad materials compatibility: since there is no high pressure spraying involved, the temperature are kept low, and cleaning cycle are kept to a minimum, solvent and vapor degreaser is excellent choice for use with the majority of components made of metal, plastic, rubber, ceramic, optic and glass; planet-friendly cleaning: because only require a small amount of electricity and do not require the use of water, Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser is very kind to the environment; lowest cost-per-part-cleaned: both the purchase and use of vapor degreaser are very economical options, a contemporary vapor degreaser can reduce the amount of solvent needed to just a few dollars per day

Machine Description

Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser

01: Application

Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser grasps the precision, efficient, environmental-friend cleaning process, which invoice condensing solvents vapor on the object that is being cleaned, the process doesn’t require any water or scrubbing instead, the Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser employs solvent vapors to clean and remove contaminants from parts made of various materials during the manufacturing process such as plastic, glass, metal, gold and ceramic in almost any industry where precision cleaning is paramount to the manufactured parts, Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser acts an cleaning pioneer in the automotive, aviation, and aerospace, medical device manufacturing, jewelry fabrication and electronic assembly industries, likely printed circuit board, relays and switches, transformers, electron-mechanical device, circuit breaker, bearings, bolts, metal hardware, cleaning medical instruments of monitoring device, oxygen and gas lines, cleaning orthopedic implants, carrier fluid like for silicone-based lubricant coatings, after decades of experimental participation in development, specified construction and appendix innovation, Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser integrates various approaches, that include solvent vapor only cleaning; vapor-spray- vapor cleaning;liquid-vapor, boiling liquid-warm liquid-vapor; spray-under, immersion, and vacuum degreasing,of note, ultrasonic cleaning can supplement nearly all of these methods

02: Parameter

Name | Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser |

Model | KLE-2060R |

Boiling Chamber Size | 1000*600*600MM |

Rinsing Chamber Size | 1000*600*600MM |

Vapor Zone Size | 1000*600*500MM |

Ultrasonic Power | 3600W |

Ultrasonic Frequency | 28KHZ |

Heating Power | 8000W |

Power Supply | 220V/415V,50HZ |

Refrigerator Power | 5HP |

Distillation Rate | 100L/H |

Re-circulation | 1GPM |

Circulation Pump | 1000W |

Diaphragm Pump | 500W |

Workload Capacity | 900*500*500MM |

Ultrasonic Cleaning | 3.6kw of power at 28khz field replacement components adjustable power and sweep |

Vapor Cleaning | Vapor Cleaning Zone above Boil tank and Ultrasonic Tank |

Spray Cleaning | Hand Spray Wand and Large spray reserve Tank |

Filtration Of Ultrasonic Tank | Continuous Filtration |

Boiling Tank Access Door | “Easy Ring” Door System |

Ultrasonic Tank Access Door | “Easy Ring” Door System |

Primary Condensing Coil | Water Chiller |

Free-Board Condensing Coil | Reciprocating Refrigerator at 28 Degrees Below Zero |

Free-Board Ratio | 100~120% |

Horizontal Slide Lid | Manual or Automatic |

Refrigerator Monitoring | Comprehensive Indicator and Temperature Displays |

Function | Vapor Degrease, Ultrasonic Rinsing, Condensation Drying, Filter Circulation, High pressure spraying Wand |

Solvent Capacity | 500L~580L |

Packaging Size | 2800*1700*1900MM |

Shipping Weight | 827kgs |

03: Salient Characters

Free-board ratio of greater than 100% to eliminate diffusion losses

Refrigerated condensing coil to condense the bulk of solvent vapor

Chilly water primary condensing coil to contain the vapor into vapor zone

Sub-zero free-board condenser to provide a cold air barrier minimizing fugitive losses

Air-tight tank lid to eliminate drafts and help seal the unit during period of inactivity

Cartridge filter to minimize solvent, timely remove the particulate and residues inside tank

Gravity water-separator continue to drain out the trapped condensed atmospheric atmospheric from the system

Stainless plumbing for solvent-wet areas

Twin arrays of cooling coils to ensure that vapor heat doesn’t affect free-board cooling

Exert heating solely as need, that can reduce solvent loss, and lowers electric expense

PLC coupled with touch screen to improve operator control and diagnostics

Refrigeration temperature and solvent level monitoring

Boiling Tank over temperature signal with solvent replacement warning

Two Stages, Solvent Vapor Submission and ultrasonic rinsing with chilly water and sub-zero condensation

Manually operated cover to control overhead air turbulence losses

Monitoring system can identify faults and notify maintenance or service is needed

High solvent temp sensor advises operator to replace the solvent

Low liquid level control to cut off the heater to advise operator to replenish solvent

Integrate high pressure hand-held spray cleaning wand as appendix

Separated liquid storage reservoir consists of cartridge filter with closed loop plumbing

Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser

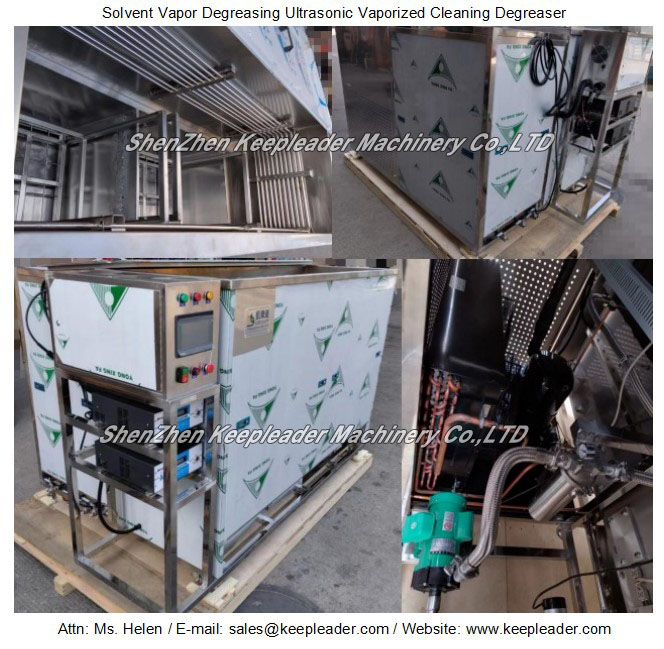

Detailed Images

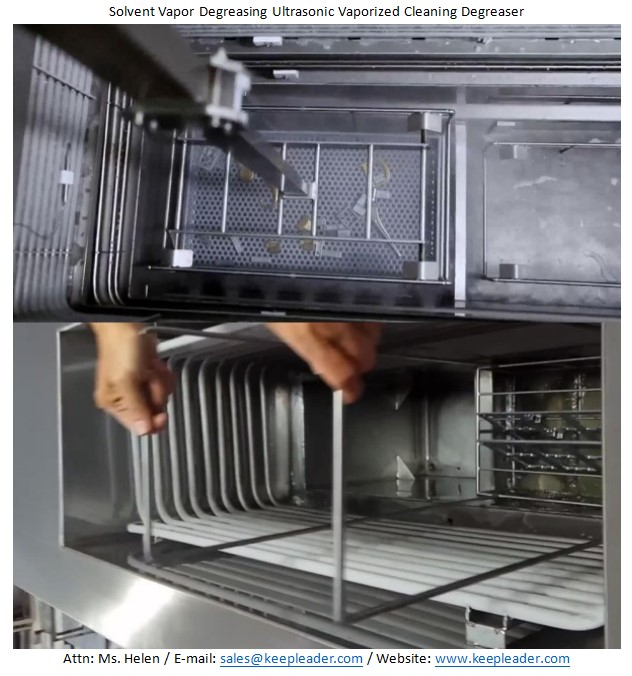

Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser gains the prevalence because of paramount in cleaning efficiency and simplified operation, the first step of the solvent cleaning process is to pour the solvent into the vapor degreaser, next, set the temperature that you want to solvent to reach, this temperature depends varies depends on the solvent your choose, different solvent has different boiling temperature, the end goal is to get the solvent to boil, which causes it to turn gaseous, after proper temperature is set, turn the vapor degrease on to initiate both the cooling coils heating element, once the vapor degreaser reaches the proper temperature and solvent is boiling, you are ready to start cleaning your parts, these last steps can either be automated or done manually, place the items that need cleaning in a metal basket and slowly lower the basket into the gaseous atmosphere, which is below the cooling coils but above the boiling solvent, allow the solvent vapor to cling to and condense on the parts, as your slowly lift the basket out of Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser, the solvent drips off the parts and falls back into the boiling solvent, leaving the parts clean and dry. The more temperature delta and more condensation, that is basic principle of enhancing the cleaning and drying performance.

Machine Uses

Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser is a machine that work much like a still, the base of the machine includes a heating elements under a reservoir known as the boiling sump, alongside the heating elements, there is a ultrasonic agitation sump of solvent rinsing, the operators usually take three steps cleaning in a cycle, step1: the heating elements heat up the solvent to boiling point, vapor forms and rises to the next level of the chamber, the hot vaporized solvent is contained in the chamber by the cooling coils located above, close to the top of chamber, parts being cleaned are slower into the vapor chamber, where the cleaning process starts, as the hot vapor surrounds the cool parts, the degreaser dissolves the dirt and begin to cool and condense on the surface, it drips back the boiling sump, taking grease and grit along with it, this step usually takes a few minutes to complete; step2: if the parts are not fully degreased after the vapor cleaning procedure or if there are textured or deep surface or channels in or outside of parts, they can be fully immersed into the boil sump to continue cleaning away grease and debris, either or ultrasonic solvent rinsing sump additionally complete penetration decontamination; step3: once the vaporized degreaser as finished condensing and has dropped back into the boil sump, the parts are ready to be lowered slowly into the rinse sump to clean away any lingering dirt, it is important to do this slowly to avoid splashing the solvent, the rinse sump is filled with clean detergent, which is continuous being recycled and purified through the cooling coils above, in addition, the filter circulation reservoir exerts continuous filtering particulates and residue, and any sediments frequency drain out from the closed-loop going-through plumbing to avoid cross contamination and improve the cleaning performance, as the recycled and purified solvent fills the rinse pump to overflow capacity, the degreasing solvent replenish the boil sump, when the rinsed parts are slowly pulled back into the vapor chamber, the degreaser once again cools the condensing before falling back into the rinse sump, the piece are now clean, dry and cooled, they are ready for the next step in the manufacturing process

Schematic Diagram

The benefits of our Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser consisting of basic configuration, cleaning procedures, performance and extraordinary appendix, such as: superior cleaning performance and effectiveness; no dependence on manual cleaning; prevents cross contamination; solvent distillation recycle for repeatable process; quick, no extra drying process is required; recycle solvent from part to another; free-board ration of 100% to minimize diffusion losses due to drafts; sub-zero free-board condenser to provide a cold barrier minimizing emission; primary chilly water condensing coil to efficiently condense the boil of solvent vapors precede reaching the sub-zero condenser; air-tight cover to eliminate drafts and minimize solvent loss during periods of inactivity; internal water separator keep all solvent within the unit at all time; recirculating pump and filter to remove particulate and extend solvent life; high pressure spraying wand freely integrate in cleaning procedures to obvious prolong condensing time and improve the efficient

Contact Us

Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser comes in a variety of configurations depending on clients’ industrial application, we usually carry sized Working Zone to gratify individual loading in maximum, that to fit not only your parts, but also your cycle time and production requirements, with today’s solvents, it is essential to size the Solvent Vapor Degreasing Ultrasonic Vaporized Cleaning Degreaser properly to ensure maximum solvent recapture through distillation cycle chilling coil, for expert assistance with your precision cleaning, attain best technology to match the best vapor degreaser machine, don’t hesitate to contact our representative to receive a free proposal

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader