Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner of Metal Degreasing_Derusting_Dirty Removing Vibration Agitation Washer

Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner

Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner adopts high frequency sound waves created by mounted ultrasonic transducers at the beneath of cleaning tank to agitate water-based bio-friendly detergents within a tank, this agitation creates micro-bubbles that implode at high force and high heat, removing grease, dirt, paint coatings, power residues and other stubborn contaminants from manufactured parts, both on production lines and in the field while water-based, this cleaning approach allows the effective clean-up of high complex part geometries, reaching holes, blind corners, cracks and recesses without harming the part surface, which incredible powerful this process called cavitation is gentle to the submerged parts, with the liquid environment quickly cooling the generated heat, manufacturers and business often prefer to use Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner because they are more environmentally friendly and employee-safe when compared with solvents, comparisons continue with aqueous baths being less regulated, more affordable and easier to recycle or dispose of properly, our Aqueous Detergent Cleaning Industrial Ultrasonic Cleaners are more effective than hand-washing, soaking or spraying, allowing for combined parts, cleaning for even greater efficiency combined with proper detergent, virtually any industrial cleaning operation can save considerable time and money

Machine Description

Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner

01: Application

Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner proves the reliable process that uses high frequency sound wave to agitate a water-soluble fluid, producing microscopic voids that, when they implode, generate a high-pressurized jetting environment that create dislodging penetration effectively at cleaning surfaces, this approach extensively applies in the cleaning of precision components in a wide range of industries, including medical, aerospace and automotive, Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner involves the high frequency sound waves, typically between 20khz and 40khz to agitate a liquid, usually water or a water-based cleaning solution, the sound waves create microscopic bubbles, or cavities in the liquid, as these bubbles more through the liquid, they create a high-energy environment that is very effective at removing dirt, grime, grease, wax, fungus, Algeria, bacteria and other contaminants from surfaces, this process, known as cavitation, occurs when the pressure in the liquid drops below the vapor pressure, causing the formation and subsequent collapse f bubbles, then these bubbles collapse, when these bubbles collapse, they release energy in the form of heat and pressure waves that dislodge contaminants from the surface being cleaned

02: Parameter

Name | |

Model | KLE-1024 |

Ultrasonic power | 1200w |

Ultrasonic frequency | 28khz or 40khz |

Plug in power | AC100~120V,60HZ / DC 200~240V/50HZ |

Cleaning cycle time | 5 minutes with Auto Shut off |

Tank material | Stainless steel |

Tank Volume | 94L |

Liquid volume | 50~60L |

Tank size | 590*400*400mm |

Overall Dimension | 720*500*600MM |

Net Weight | 110kgs |

Packaging Volume | 0.57CBM |

03: Salient advantage

Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner gains popularity because of its affordable, reliable and user-friendly approach of decontaminating items that are otherwise difficult to clean, it is also known as a ultrasonic bath because it uses high frequency sound waves to create cavitation bubbles which agitate the surface causing abrasive particles to be removed, Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner offers several benefits such as subsequent phenomenon.

031: quick and effective cleaning: Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner can reduce the time taken for any kind of cleaning process significantly, this makes ultrasonic cleaners ideal for use in busy settings such as commercial kitchens, restaurants and hospitality establishments, due to its ability to reach tiny crevices and cracks, it can effectively remove dirt, great, and grime even from complex porous object with intricate details

032: Non-tonic and Eco-friendly: Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner are non-toxic as it uses only small amount of water, detergent solution, and ultrasonic waves to clean, this makes it a safer choice compared to other cleaning approaches that may invoice the use of harsh chemicals or abrasive scrubbing tools, moreover, since this approach is don’t require any hazardous waste products, it helps maintain an eco-friendly environment

033: Cost Effective: using an Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner can be cost-effective in the long run since you don’t need to replace parts due to wear and tear from abrasion caused by traditional cleaning approaches, additionally, you will save time b eliminating prepared cleaning steps such as soaking and scrubbing.

034: Enhanced Performance: After an ultrasonic cleaning, your items will be restored to tis original condition, allowing for optimal performance and longevity, additionally, you can help reduce the chances of malfunction due to dirt or grime buildup on critical components

035: versatility: Aqueous Detergent Cleaning Industrial Ultrasonic Cleaners are extremely versatile and can be used to clean a wide range of different materials ranging from glassware to jewelry and firearms, this makes them a great tool for businesses that need to clean multiple items in various industries

Overall, using an Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner is the best approach to guarantee your working-pieces are decontaminated thoroughly and promptly avoiding possibility of any hassle or mess, definitely sort to a cost-effective and eco-friendly approach that provides many advantages that cannot be achieved with traditional washing approaches

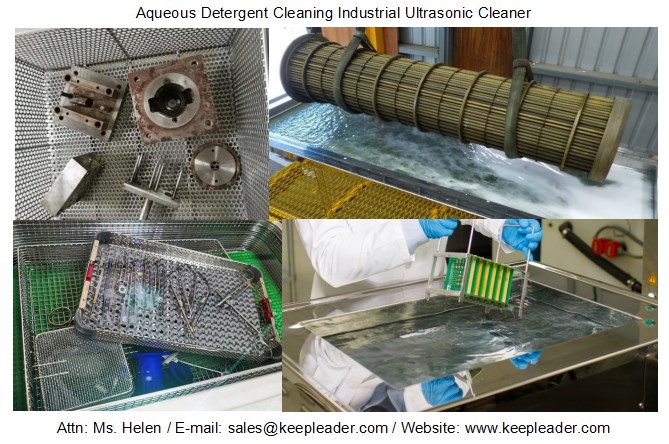

Detailed Images

During the ultrasonic scrubbing procedure, ultrasonic sound waves create cavitation activity which produces a superior cleaning penetration that removes particles that can be embarrassed or impossible to dislodge with manual approaches, mechanical removing forces are present throughout the fluid, so Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner can remove debris, grime, dirty, dust and particles from 360 degree direction of the parts, including locations that are not accessible by hand, additional advantage is that Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner typically requires a short cycle time, dirt, grease, and other contaminants are easily removed in a matter of minutes, this prevents corrosion and pitting on metal components and significantly decreases downtime, while the effectiveness of Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner leads many to assume its harsh cleaning approach, it is actually a very gentle, environmentally-friendly process, it avoids the use of abrasive or harsh chemicals and is safe to use on a range of materials without damaging the object’s underlying structure or finish, one more benefit of an Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner is that its highly tailored, you can purchase the most suitable tank size for your needs, and create the ideal process flow for your application, you can even choose from a range of automatic parts washer that minimize manual input, the potential for customization and quick processing time making Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner an extremely cost-effective approach in many industries

Machine Uses

Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner benefits many pragmatic cleaning process in industrial settings, that applies to clean most types of surfaces including metal, plastic, composites, ceramics and rubber, one popular use is in manufacturing setting where ultrasonic cleaning can be applied to various industrial parts, from molds and dies to wires and electronic circuit boards, additionally, this process can be used for degreasing metal components prior to painting or powder coating, protecting against corrosion or wear and tear, Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner is often used in the automotive and aerospace industries to clean engine components, gear and bearings, the process remove oil, grease and carbon deposits that are otherwise difficult to remove additionally, Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner can help reduce wear and tear on these components by removing any embedding particles which can cause damage over time if left untreated, Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner is also commonly used to decontaminate medical device such as dental instruments, surgical tools, and more, medical device decontamination, requires extremely effective cleaning processes to ensure patient safety, ultrasonic technology eliminates bacteria from hard-to-reach places within medical devices with minimal physical contact required from personnel, another use for Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner is surface preparation prior to welding or bonding operations involving metals such as aluminum alloys and stainless steel, by removing light oils and other contaminants from surfaces, manufacturers can create stronger and more reliable products that those produces using traditional approach, Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner may be used to clean everyday items such as firearms and musical instruments, and these systems are not just limited to cleaning, for instance, an ultrasonic cleaning tank is often used in the passivation of stainless steel

Contact Us

Our specialists of Aqueous Detergent Cleaning Industrial Ultrasonic Cleaner are committed to sharing their expertise, our team maintains and improves cleaning process, exceeding the expectations of all our partners and customers, start your journey of experiencing tested and proven cleaning products with consistent, reliable results, our advanced critical cleaning solution come with customer support, product training and troubleshooting assistance, we offer free consultations for any cleaning processes, including tabletop, standing-along and automatic transferring immersion and ultrasonic cleaning, we are a partner you can count on to assist you on navigate your precision parts cleaning needs

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader