Servo Ultrasonic Plastic Welding Machine of Super Precision_Intelligent_Digital Thermoplastic Assembly Frequency Chasing Welder

Servo Ultrasonic Plastic Welding Machine

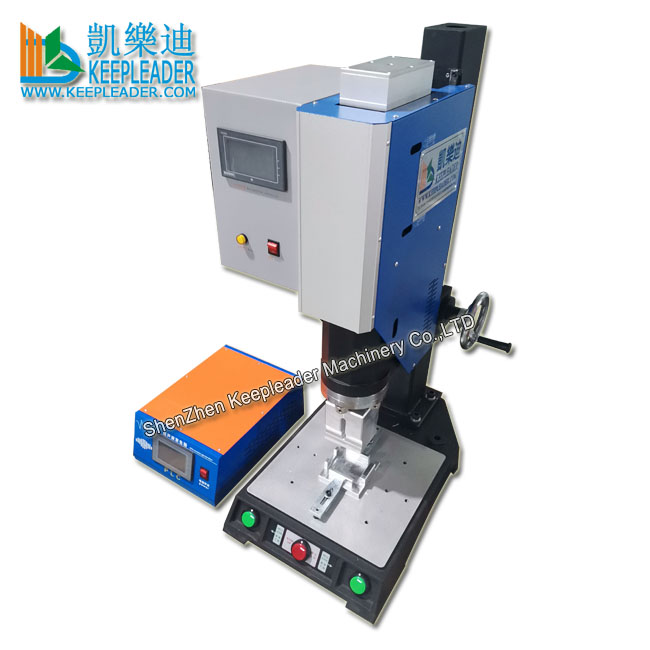

Servo Ultrasonic Plastic Welding Machine is specially designed to meet the need for the assembly of smaller and more intricate plastic components, the servo driven enables free positioning of the stake and ensures speedy stroke motion, by programming ultrasonic stack velocity, force and position throughout the entire welding process, our Servo Ultrasonic Plastic Welding Machine ensure fast and consistent production, resulting in stronger welds

Machine Description

Servo Ultrasonic Plastic Welding Machine

01: Application

Servo Ultrasonic Plastic Welding Machine is exceptional ultrasonic welder, that integrates servo control in thruster activation of programmable logic control, because of its accurate control of velocity, melting, holding and travelling, Servo Ultrasonic Plastic Welding Machine is obviously pioneer that conventional pneumatic actuated ultrasonic plastic welder, particularly for precision plastic assembling field, such as automotive industry: joining various plastic components in the interior and exterior of vehicles, such as door panels, dashboard components, lights and air vents; electronics: bonding plastic parts in electronic devices including the assembly of casings, connectors and other components; medical devices: assembling medical device, such as disposable syringes, IV components, blood filters, and other plastic parts used in healthcare applications; packaging: sealing and welding plastic packaging materials such as blister packs, clam-shells, and other types of packaging used in the food, pharmaceutical and consumer goods industry; consume goods: joining plastic components in the production of household appliances, toys and other consumer products; textile industry: welding and sealing synthetic fabrics and textiles in the production of clothing, bags, and other textile products; aerospace: assembling plastic components in the aerospace industry, where lightweight and durable materials are crucial; electronic components: jointing plastic parts in the production of electrical components such as connectors, switches and housings; toys and games: assembling plastic parts in the manufacturing of toys, games and recreational products; appliances: jointing plastic components in the production of appliances such as washing machines, refrigerators and vacuum cleaners; filters and seals: welding plastic filters and seals are used in various industries, including automotive, HVAC, and industrial applications; footwear industry: welding and bonding plastic components in the production of shoes and other footwear; renewable energy: assembling plastic components in the manufacturing of renewable energy products such as solar panels and wind turbine components; custom packaging solution: creating custom packaging solution for unique product requirements providing secure and tamper-evident seals; stationary: joining plastic components in the production of stationary items such as pens, folders, and other office supplies

02: Parameter

Name | |

Model | KLC-2615S/KLS-2020S |

Electric Connection | AC220V±5% 50/60Hz or AC110V±5% |

Ultrasonic Power | 2600w/200w |

Ultrasonic Frequency | 15khz/20khz |

Machine Journey | 100mm |

Z-Axis Accuracy | ±0.01mm |

Generator Alarm | Abnormal Freq, Over current/Load, excessive Temperature |

Triggering Method | Position, Pressure, pressure drop |

Welding Method | Welding Time/Relative Position/Absolute Position/Welding Energy/Peak Power/Max Pressure/Grounding Detect |

Piling Function | Time/Position/Energy/Pressure |

Output Interface | Color Screen |

Motion Control | Servo Motor |

Frequency Adjustment | GBT Auto-Tuning |

Maximum Welding Time | ≤5 S |

Input Voltage | 110v.60hz or 220v, 50hz |

Oscillation Time | 0.001 Thru 9.99s |

Welding Capability | Diameter: 200mm |

Operation Switch | Two-hand Start, emergency brake bottom at front |

Dimension | Digital Generator:440*130*280mm |

Overall Dimension | 500*700*1638mm |

Weight | Press: 168kgs |

Weight | Digital Generator: 10kg |

03: Salient Character

Shorter thruster height to pack more power in a compact increased booster rigidity for better weld repeatability

Travelling sensor generate distance signal,that provides instant feedback at a convenient location of load cell

Integrated Servo controller, fewer interconnected cables, and improved cable handing for small footprint and overall appearance

Closed-loop control of load cell to apply accurate ultrasonic initiation, collapse distance, solidifying time and velocity control

Linear encoder achieves monitoring top home position of thrust and triggering ultrasonic

Simplified control of force calibration, distance and velocity verification

Provide the control necessary for fine-tuning critical application, process monitoring

Multiple language operative software tp freely select in different scenarios

Programmable Logic control with touch screen assists on convenience and quick accessibility in setting, operation and query monitoring

Operators can refer to each pragmatic welding cycle to gain the utmost performance during matching, clarification, duplication and clone of working parameters

Intelligent ultrasonic generator can auto completion of frequency tuning and matching, and keep the resonant at its prominent performance

Detailed Images

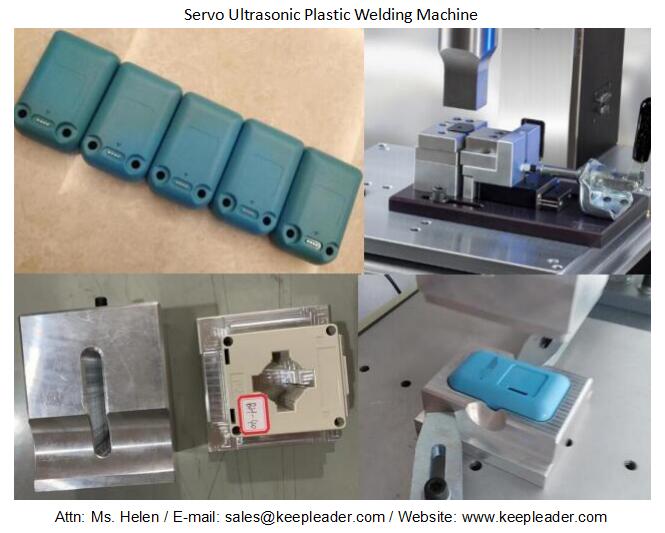

Servo Ultrasonic Plastic Welding Machine offers intuitive process setup controls, robust mechanical design of compact structure, bilingual operation software for international market. Integrated servo system impels accusation and consistency in welding quality, advanced weld initiation trigger methods include our thrust distance trigger, eliminating all mechanical trigger settings, and significantly improving weld initiation accuracy and repeatability, Servo Ultrasonic Plastic Welding Machine offers unparalleled advanced features and controls, its operational simplicity and robust design ensure consistent and reliable welding results every cycle, using our heading-edge Servo Ultrasonic Plastic Welding Machine, keepleader’s application engineers can ensure that your assemblies meet or exceed the application requirements and quality standards, we provides a full lab report detailing setup conditions, process parameters and power and velocity basing on your welding samples, referring to this data during production can help ensure assemblies with consistent welding quality

Machine Uses

Servo Ultrasonic Plastic Welding Machine can match welding speed to the melt flow rate of the plastic because of servo actuation, Servo Ultrasonic Plastic Welding Machine is mostly used in the automotive consumer. Electronics, or medical, industries where permanently strong, tight and visually impeccable connection are required with all ultrasonic welding machines, the ultrasonic generators guarantee reproducible results, the weld process is easy to optimize with specially developed controllers and suitable software, if you are not sure which ultrasonic plastic welder is best suited for your operations, contact us today so we can help guide you towards the most efficient solution

Contact Us

Servo Ultrasonic Plastic Welding Machine is prevalent model in plastic assembling connection, lkeepleader, we are professional supplier of the customized acoustic tool and fixtures to gratify individual production, our capability and service impel our steady development, such as, your one-stop place for high-end welding technology solutions; reliable product quality: our ultrasonic plastic welding helps you meet project deadlines, maintain quality, and boost efficiency for a great return on investment; free design and model selection: our technician will help you with free design and to choose welding machine to fit your different sized products and special materials; free training and lifetime support: no experience? no problem, our engineer will assist you with free application guidance to ensure optimal use and offer maintenance service

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader