Vacuum Cleaning Ultrasonic Cleaner Machine of Triple Tanks_Aqueous Vacuuming Immersion Bath Washers Ultrasound Washing Equipment

Vacuum Cleaning Ultrasonic Cleaner Machine

Vacuum Cleaning Ultrasonic Cleaner Machine has multiple procedures in precision parts in vacuum condition, includes ultrasonic coarse cleaning/ultrasonic precision cleaning, ultrasonic soak rinsing and hot air drying, additional processes are acceptable, such as immersion cleaning, metal molecular passivation, high pressure spray cleaning, multi-frequency ultrasonic cleaning tank or rinsing tank and etc, high frequency sound waves under vacuum tank that separate contaminants from a wide variety of parts, including electronic components, medical devices, and lab equipment, Vacuum Cleaning Ultrasonic Cleaner Machine come in a wide variety of models which simplified designs and a full range of features to meet any precision cleaning requirement quickly, consistently and cost effectively

Machine Description

Vacuum Cleaning Ultrasonic Cleaner Machine

Application

Vacuum Cleaning Ultrasonic Cleaner Machine is composed with three chambers, which are execute cleaning procedures in vacuum condition, the three steps cleaning processes consist ultrasonic agitation cleaning combined with filtering circulation in first tank, ultrasonic soak rinsing in second tank, and ultimate turbulence hot air drying in third tank, these specified processes all are in vacuum environment, that is pragmatic proven successful in utmost performance in precision parts washing, such as rubber, plastic, bearings, bolts, transmission components, engine parts prior to assembly, plastic injection molds and more, in addition to industrial/manufacturing environments, they are ideal for automotive, medical, pharmaceutical, aerospace, aviation, airspace, engineering and other industries

Parameter

Name | |

Model | KLE-3024 |

Power Voltage | 380v,50hz,3phase,5wires |

Ultrasonic Power | 2600w |

Heating Power | 12kw |

Material Loading/Unloading | Manual |

Optional Features | Auto Transmission Manipulator |

Filtering Circulation | Communicating Vessel Connected with first ultrasonic cleaning tank, after filtering, the fresh water is being pumped into rinsing tank, at last overflow into first ultrasonic cleaning tank |

Weight | 600kgs |

Size | 2500*1200*1600mm |

Configuration of Fist Chamber | |

Function | Ultrasonic Agitation Coarse/Precision Cleaning |

Internal size | 600*500*500 |

Ancillary Function | Independent Filter Circulation |

Ultrasonic Power | 1300w |

Ultrasonic Frequency | 28khz |

Heating Power | 2kw |

Tank material | SUS304,312stainless steel Vibrating Spectrum |

Tank Thickness | 2mm |

Tank Capacity | 150L |

Transducer | 26pcs |

Temperature Setting | 0~100 Celsius Degree |

Filtering Power | 500w |

Filtering Particle | 20um |

Drain Valve | Yes |

Water Inlet/Outlet | Yes |

Configuration of Second Chamber | |

Function | Ultrasonic Jet Flush Rinsing |

Internal size | 600*500*500 |

Ancillary Function | Jet Flushing |

Ultrasonic Power | 1300w |

Ultrasonic Frequency | 40khz |

Heating Power | 2kw |

Tank material | SUS304,312stainless steel Vibrating Spectrum |

Tank Thickness | 2mm |

Tank Capacity | 150L |

Transducer | 26pcs |

Temperature Setting | 0~100 Celsius Degree |

Drain Valve | Yes |

Water Inlet/Outlet | Yes |

Configuration of Third Chamber | |

Heating Power | 6kw |

Internal Size | 600*500*500mm |

Pumping Impeller | All angular direction of Turbulence Hot Air |

Salient Characters

Precision filtering system can dialyse tinniest particulars of scales is 20um

All stainless-steel construction, including frame, tanks, sealing cover, plumbing, and filtering system

Recessed countertop for fluid spill containment

Programmable Logic control with touch screen

Digitally queries and monitor cleaning performance to guarantee quality

Low voltage electrical controls for safe operation

Direct-bonded piezoelectric ultrasonic transducers

Multiple ultrasonic frequencies are arranged in two functional tanks

Minimal footprint to save the working space

User-friendly design, operation and maintenance of a more rational intelligent ventilation system, external order

Cleaning device has a vacuum degassing to enhance ultrasonic cavitation

With sealing cover to generate vacuum working condition

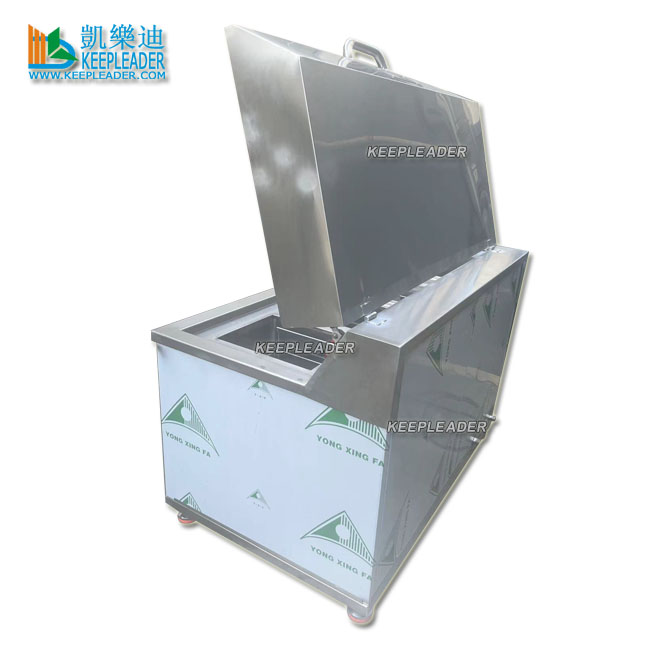

Detailed Images

Vacuum Cleaning Ultrasonic Cleaner Machine differs with conventional ultrasonic cleaning machine, its vacuum condition, multiple tanks of combined cleaning procedures obtains pioneer advantages in precision parts cleaning, ultrasonic scrubbing tank have degassing system, usually the liquid contains air under normal pressure, liquid will be suffer from the air blocking in ultrasonic and influence the cleaning effect, but, the degassing system solve the problem that the air secedes the liquid and dragging off the air gas working parts between slit, blind holes, crevice and crack, hook and cranny and tiny holes, make the liquid can be go ultrasonic cleaning under no air condition, the double effect improves washing level greatly, vacuum cleaning and drying system: the clean effect will be better when the liquid temperature will higher than boiling under vacuum condition, cleaning liquid quickly siphoned off vacuum to make working parts fast drying

Machine Uses

Vacuum Cleaning Ultrasonic Cleaner Machine is aqueous immersed cleaning under ultrasound molecular bubbles jetting in vacuum status, the inner size of cleaning tank will comply with your practical dimension in a circle cleaning

Contact Us

After evaluating various Vacuum Cleaning Ultrasonic Cleaner Machine in the market, it is clear that selecting the best Vacuum Cleaning Ultrasonic Cleaner Machine is crucial for effective cleaning results, each product reviewed offers unique features and benefits that cater to different cleaning needs, with advanced technology and user friendly design, these Vacuum Cleaning Ultrasonic Cleaner Machines provide efficient and thorough cleaning for a range of items, particularly for precision metal parts, investing this Vacuum Cleaning Ultrasonic Cleaner Machine can save your time and effort, make your cleaning routine easier and more effective at affordable price

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader