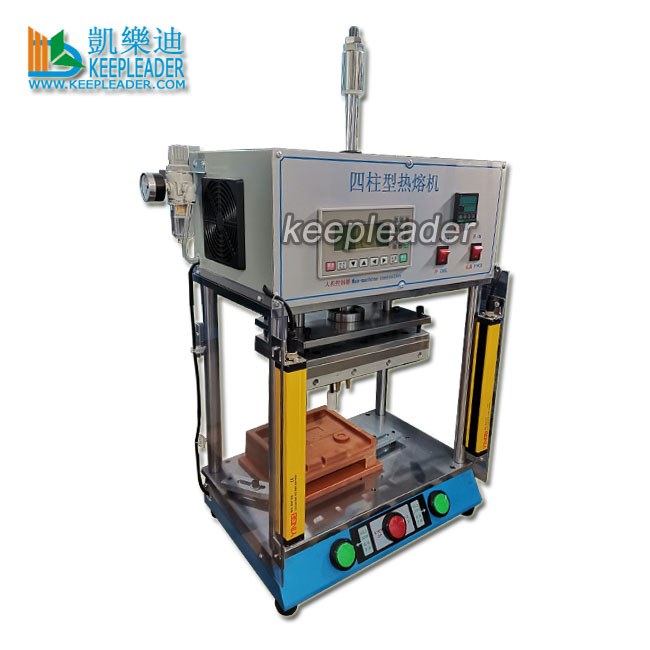

Plastic Welder Hot Melt Welding Machine of Semiautomatic_Four Column_Pneumatic Actuation_Thermostatic Heat Fusion_Staking Device

Plastic Welder Hot Melt Welding Machine

Plastic Welder Hot Melt Welding Machine adopts a plate-drawing structure and uses an electric heating approach, the whole machine is in the form of a frame, composed of three plates, and upper template, a lower template, and a hot template, and is equipped with a hot mold and an upper and lower plastic cold mold. The action mode is pneumatic control, mainly suitable for welding plastic such as household appliances, car lights, the heating power and mold size can be set according to the size of different plastic parts to realize the welding of various plastic parts, with simple operation and convenient use

Machine Description

Plastic Welder Hot Melt Welding Machine

Application

Our Plastic Welder Hot Melt Welding Machine is designed by the principle of electric melting, that integrates with pneumatic driven mechanism in process of thermoplastic embossing, sealing, edge trimming, stamping, foil decoration, profile forming, screw inserting, molding and etc, digital temperature controller can adjust and monitor heating temperature in precisely, unified pressure applied can execute continuous displacement to gain perfect welding deforming performance, that acts an alternative solution for ultrasonic welding machine, that is not weldable for large-scale and specific profile welding geometries, it is suitable for welding PP, PE, Nylon and other thermoplastic work pieces, such as water tank, oil tank, brake liquid cans, battery, motorcycle filter, direction light, bumper, washing machine plastic balance circle, construction doors and windows, mobile phone casing, phone antenna, computer keyboard and interior, telephone, car lights, car dashboard, outdoor refrigerators, door panel, vacuum cleaner, hole ball and other plastic that require plastic welding, inserting of copper nuts for fixing phone cases, specially suitable for automobiles, electronics and appliances

Parameter

Name | |

Electric Connection | 350v,50hz, 3phase |

Heating Power | 1800w |

Electric Current | 8.5A MAX |

Plastic processed | PPO/PP/PSO/PS/PPS/PET/PE/PC |

Welding Area | 300*300mm |

Stroke Distance | 750mm |

Operation Trigger | Two hand Simultaneous |

Air Pressure | 0.4~0.6Mpa |

Ambient Temperature | -5ºC~40ºC |

Ambient Humidity | 20~80% |

Dimension | 650*400*900mm |

Weight | 80kgs |

Salient Character

Divisional temperature controlling function to ensure even welding

No need any adhesive, flux to weld, and less heat consumption

Robust structure, four column leading sliding board for Unity pressure

Programmable logic control with touch screen for easy operation and monitor

Welding area and welding range are wider

Double Triggering buttons to improve the security

Integrated design that can move conveniently and efficiently

Compact Frame to gratify removing production scenarios

Pneumatic driven of pressing mechanism to guarantee the sufficient pressure

Detailed Images

Plastic Welder Hot Melt Welding Machine fabricates pioneer characters, such as adopting dual button startup to improve the practical safety; assembling renown components to ensure highly accurate longevity; the combination of hydraulic buffer and buffer circuit ensures smooth operation; the main electrical components of the Plastic Welder Hot Melt Welding Machine are all well-known products from Taiwan, Japan and the United States, with beautiful appearance, durability, and reliable quality; equipped with electronic buffering and electronic limiting; suitable for various hot melt approaches likely embedding and riveting; the guide column of the Plastic Welder Hot Melt Welding Machine takes an extended linear bearing design, ensuring smoother mechanical travelling and high accuracy

Machine Uses

Plastic Welder Hot Melt Welding Machine is lightweight and exquisitely designed. It is extremely easy to transport and install, movable locking mold design make it easier to replace the upper and lower molds, greatly reducing production costs and improving production efficiency, the four column structure is robust and compact that has elegant appearance, convenient in operation and high in production efficiency, it is equipped with fixed bottom mold, which can be equipped with multi molds for production in the form of assembly line, the bottom mold can be moved at will, the mold is easy to adjust.

Contact Us

Plastic Welder Hot Melt Welding Machine adopts electric heating melting and pneumatic driving mechanism to implement thermoplastic welding, assembling, embossing, stamping, edge cutting, reforming and molding, that gratify majority of plastic assembling process at affordable price, all our tech team have profound knowledge and expertise in machinery, and they are continuous driven forwards achieving fame and recognition, their tremendous efforts enable us in offering maximum client satisfaction, thereby strengthening our position in market, try to create a initiation to prove our ability and reliability

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader