Wire Foil Printing Industrial Marking Hot Stamp Printer Heat Press Imprinting_Coding_Embossing_Auto Length Cutting Cable Marker

Wire Foil Printing Industrial Marking Hot Stamp Printer

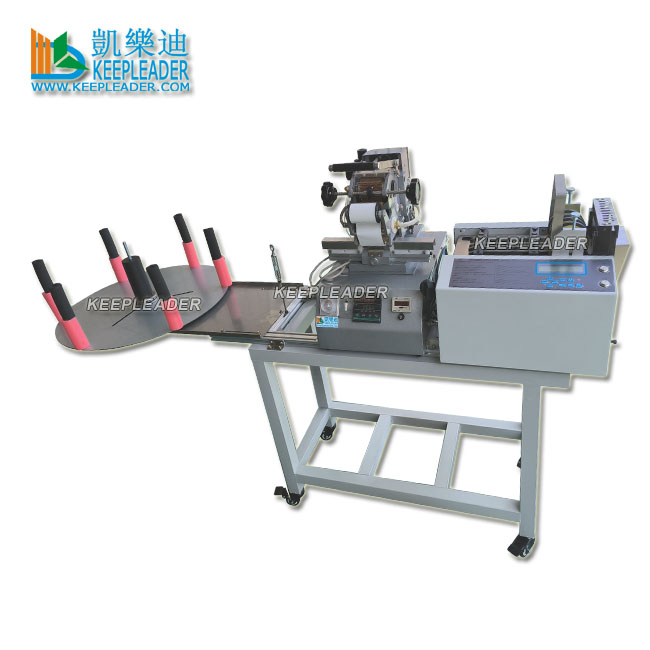

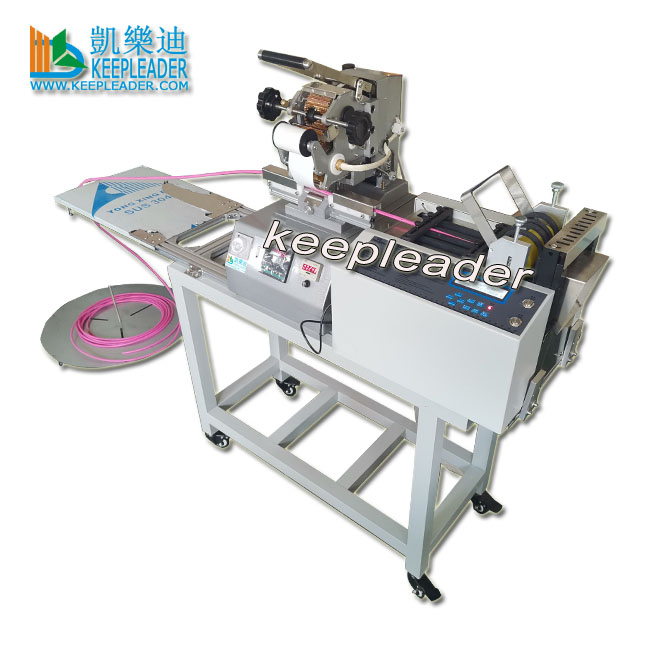

Wire Foil Printing Industrial Marking Hot Stamp Printer are available in two configuration, manual printing or automatic cutting and printing in one machine, to meet both your application requirements as well as your budget, both configurations can be easily interfaced with your other wire processing machines, likely wire end stripping machine, whatever printing and cutting process has small footprint makes them easily integrated into exiting production lines, the workable thermoplastic material includes wire/cable insulation, flexible plastic sleeve, sheath, and tube, the user has the ability to make a wide range of materials, another nice feature of our Wire Foil Printing Industrial Marking Hot Stamp Printer is the automatic wire feeding mechanism, that can continue print and interval cut the wires

Machine Description

Wire Foil Printing Industrial Marking Hot Stamp Printer

Application

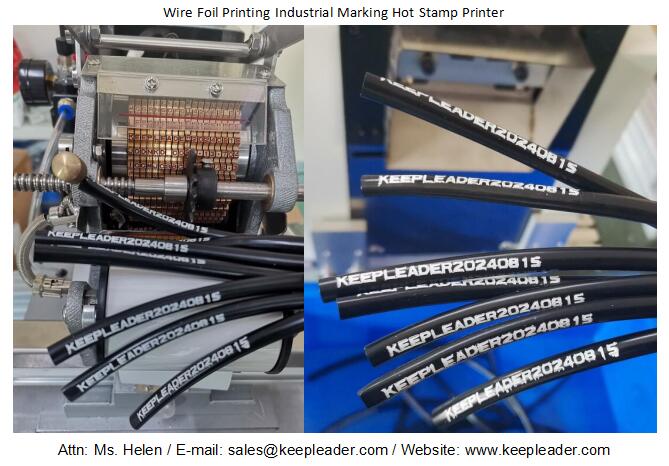

Wire Foil Printing Industrial Marking Hot Stamp Printer is our latest combination of wire hot foil printing machine and wire interval cutting machine, two machines are installed into auto feeding mechanism of wire in roll to gain totally automatic production of wire/cable/sleeve/sheath/tube marking and cutting process at economical and high quality output, the cutting length and printing location both are adjustable, that is computerized in controlling and monitoring, the combination of characters and character size can be selected freely within the specific range, this automatic Wire Foil Printing Industrial Marking Hot Stamp Printer is suitable for marking thermoplastic material, such as wire/cable insulation, flexible sheath, sleeve and tube. During the process, the heated character wheels imprint the precision-engraved character by pressing the pigment marking foil into the selected material, the concave form of characters is exactly matched to the diameter of the processed material, the precise adjusting options for the stamping pressure an time and the marking temperature allow to recall every results

Parameter

Name | |

Model | KLS-1824C |

Power Supply | 220v,50hz |

Raw Material Diameter | 1.2~20mm |

Marking Pressure | 0.1~0.7Mpa adjustable |

Marking Temperature | 0~200 Celsius Degree |

Stamping Time | 0.1~3.0s |

Compressed Air Connection | 10Mpa/10Bar |

Options | Foot pedal or automatic in-line operation |

Number of wheels | 18 or specified |

Characters per wheel | 40 characters per wheel |

Wheel configuration | A to Z; 0 to 9; -/. and blank |

Character Size | Horizontal: 1.2-3.0mm |

Vertical: 0.2 and 1.6mm or specified size | |

Marking Foil | PVC-Foil, Teflon-Foil |

Color: White, Blank, or request | |

Foil usage per mark: 3mm adjustable | |

Measure | 1800*520*1120mm |

Weight | 128kgs |

CE conformity: Fully complies with all CE and EMC equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility | |

KEEPLEADER recommends that wire samples be submitted in cases where there is doubt as to the processing capabilities of a particular machine | |

Salient Characters

Sliding gear to manually dial character wheels for shortest changeover times

Most important changeover operations possible without tools

Two sets of rotary wheels, one set is used for indexing, the other is for printing

Quick-change fixture system minimize set-up time and max printing speed

Prints horizontally or vertically along the wire

Utilizes full-size, 40 character type-wheels

Printing and cutting process in line for optimal output

Stroke adjustment to ensure maximum production rate based on wire size

Large selection of character sizes and foils

Standard V-block wire guide allows marking on cable up to 20mm diameter

Closed loop integral temperature controller

Legends are set in seconds, no handing of hot type or waiting to operate

Functions are controlled and monitored by microprocessor-based PLC

Programmable printing control and monitor

Cutting length, and printing location both are adjustable

Wire Foil Printing Industrial Marking Hot Stamp Printer complies with CE relative guidelines

Detailed Images

Wire Foil Printing Industrial Marking Hot Stamp Printer takes advanced combination to improve the productivity at affordable price, such as automatic feeding and cutting of wire/cable/tubes with an outside diameter: 1.2~20mm; cutting length and printing location are adjustable as specification; quickly change fixture and select the characters for free combination

Machine Uses

Wire Foil Printing Industrial Marking Hot Stamp Printer is used for identification and labeling of wiring in the switchboards and control panels, power plants, railroads, aircraft, ships, industrial robots, machine tools, home appliances and high-voltage substation for buildings and condos all need switch boards and control panels, its advance focus on printing and cutting process in one automatic machine

Contact Us

Wire Foil Printing Industrial Marking Hot Stamp Printer is innovative combination of wire cutting and printing in a production line, that is productive effectiveness and cost efficiency in wire/cable/flexible sleeve, sheath, tube identification coding process, keepleader, we have a rich experience and how-how in wire marking solution backed by over 10 years' experience, we are always committed to print quality and have consistently improved our printing technology over time, and beside repair services, the user can check our website or sales representative for updated fabrication, contact us now to find more what we can do for your business

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader