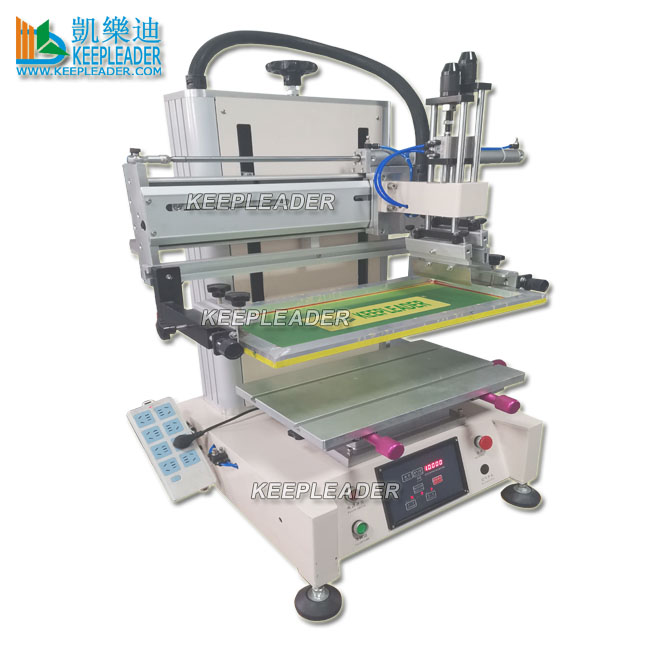

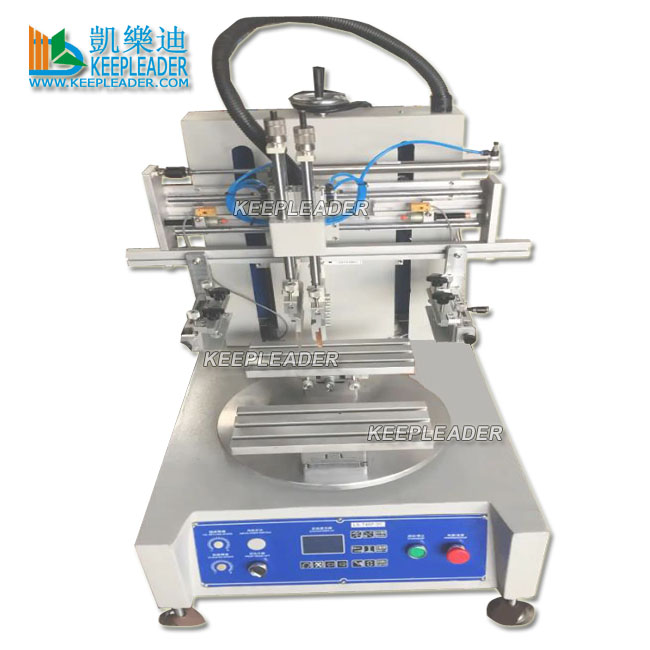

Silk Screen Printing Machine of Semi-Automatic_Desktop_Flatbed_Logo/Label/Text Mesh Frame Single Color Serigraphy Screen Printer

Silk Screen Printing Machine

Silk Screen Printing Machine, also known as serigraphs printing machine, is a traditional method that involves the use of mesh screen/stencil to transfer ink onto a substrate, the process involves blocking out area of the screen that are not mean to be printed on, leaving open spaces for the ink to pass through, the ink is then pressed through the screen with a squeegee/rubber scraper and onto the surface of substrate, it offers some of most elegant results, its vibrant designs and graphic styles make Silk Screen Printing Machine popular among customers

Machine Description

Application

Silk Screen Printing Machine is a versatile ink printing technique that can be used in a wide range of decorations, from apparel printing and signage to packaging and fine art prints, the process is efficient, cost-effective and high customization, making i an attractive option from businesses, organization, industrial production and artiest alike, whether you are looking to create a custom t-short design, produce high-quality signage, luxury furniture or create a one-of-a kind fine art print, Silk Screen Printing Machine is a technique that is worth considering and optimal selection

Parameter

Name | |||||

Model | KLS-2030T | KLS-2030C | KLS-2030P | KLS-2030X | KLS-2030Q |

Feature | Slot | Air-Taking | Moving-Table | Rotary Table | Curved |

Power | 220v,50hz or 110v,60hz Single Phase | ||||

Print Size | 200*300mm | ||||

Horizontal Travel | 350mm | ||||

Vertical Travel | 160mm | 160mm | 80mm | 80mm | 80mm |

Air Pressure | 5~7Bar | ||||

Weight | 60kgs | 60kgs | 80kgs | 150kgs | 65kgs |

Speed | 800Pcs/h | 800Pcs/h | 500Pcs/h | 1200Pcs/h | 800Pcs/h |

Frame Size | 400*600mm | ||||

Worktable | 250*450mm | 600mm | Circular | ||

Salient Character

Compact structure, that occupy the small space

Involving fewer manpower, and it is easy to print color

It is widely used in apparel, CD fabric, bags, umbrellas, leather and etc

Table plate can be moved around, and screen can also be around

Mesh frame can be precisely set to correct position by tuning screws

Color steel press with stand, and literally no maintenance

The head comes assembled and ready to attach to the base

All tubular steel construction for good longevity

Adjustable screen tension holds down

Maximum precision, consistency and print quality

Simple to learn and maintain, get up to speed quickly

Buying Guidance

Printing with Silk Screen Printing Machine requires some to ensure that the print is of high quality, here are some techniques to follow when printing with Silk Screen Printing Machine:

Flood the screen: before printing, flood the screen with ink, this means that you should apply a layer of ink over the entire screen to ensure that the link is evenly distributed

Use the right around the pressure: when printing, use the right amount of pressure to ensure that the ink is transferred to the fabric or paper accurately, too much pressure can cause the ink to bleed, while too little pressure can result in faint print

Print in layers: if you are printing more than one color, print each color in layers, this means that you should print one color a a time, allowing each layer to dry before printing the next color

Troubleshooting common printing issues

Printing with silk screen can sometimes lead to some common issues, here are some troubleshooting tips to help you to resolve these malfunctions

Ink bleeding: if the ink is bleeding, it means that there is too much pressure on the press, to resolve this issue, reduce the pressure and try again

Incomplete print: if the print is incomplete, it means that there is not enough pressure on the press, to resolve this issue, increase the pressure and try again

Uneven print: if the print is uneven, it means that the link is not evenly distributed/dispersed on the screen, to resolve this issue, flood the screen with ink before printing

Detailed Images

Silk Screen Printing Machine is a method of serigraphy printing that involves the use of fine mesh screen that is stretched over a frame made of aluminum, wood, the screen is coated with a light-sensitive emulsion and design is created on a separate piece of film or paper, the film is then place on the screen, and a light is shone through it, exposing the emulsion to the light, the areas of emulsion that are exposed to the light harden, while the areas that are not exposed remain soft and wash away with water, this creates a stencil or template on the screen that allows ink to pass through only certain areas, creating the specified design to apply ink distribution in typography

Machine Uses

Silk Screen Printing Machine is a versatile printing technique that can be used on a wide range of surfaces, from fabric and paper to glass and plastic, ceramic, in this section, we will explore the different application of Silk Screen Printing Machine including apparel printing, signage and banners, packaging and label and fine art prints, the benefits of this technique are following

High quality: one of the most prominent qualities of Silk Screen Printing Machine lines in that for this technique we use thicker inks that in other digital printing methods, the use of thicker ink, in turn, results in more vibrant colors that help add boldness to the print, this technique is also suitable for adding different qualities to the print, it can accommodate specialty ink, such as fluorescent or metallic inks, that complement the visual design

Customizability: besides using a variety of ink, Silk Screen Printing Machine also utilizes a variety of colors, stencils help create distinct logos and graphics that help cater to the needs of different brands, multiple-layer Silk Screen Printing Machine offers freedom in design, it can be used to achieve different patterns and textures that complement designs by adding more depth to the visual appeal

Versatility: Silk Screen Printing Machine is suitable for various materials, it can be used to print brand logos or decorations onto both smooth and texture surfaces, this can be anything from paper boxes t irregularly shaped glass jars, it also works well with textiles and can be used in printing cotton, polyester, silk, wool and more

Durability: Another advantage of the thick inks we use in Silk Screen Printing Machine is their immense durability, these inks help create a dense layer of pain over the textile, which is difficult to scratch or remove, these prints are also resistant to UV lights and moisture, meaning they will not fade or lose their composure, so, screen printed design will likely last longer that other digital prints

Contact Us

Silk Screen Printing Machine is versatile and appealing option for producing high quality, clean and professional prints as it offers a range of advantages such as its vibrant output, high opacity, durability and its flexibility in design placement, and material options, its cost-effectiveness for large-scale projects further enhances its appeal, however, its crucial to acknowledge the limitation of Silk Screen Printing Machine, including the higher costs for multi-color prints, reduced feasibility for short print runs, and challenges with highly complex designs or extreme detail, additionally, the slower turnaround time compared to digital printing must be considered, especially for time-sensitive projects, be carefully evaluating these factors, you can make informed decisions about whether Silk Screen Printing Machine aligns with your specific printing needs, it is always best to consult with experienced industry professionals as they can offer valuable insights for your specific project requirements, quality expectation and budget constrains, keepleader is the reliable manufacturer of Silk Screen Printing Machine for the graphic and textile industries, setting the standard for innovation, quality and service, don’t hesitate to contact us to gain more what can do for your business

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader