Wire Marking Machine Cable Hot Stamping Foil Printer of Automatic Feeding_Cutting_Printing_Heat Press Labeling Code Wiring Marker

Wire Marking Machine Cable Hot Stamping Foil Printer

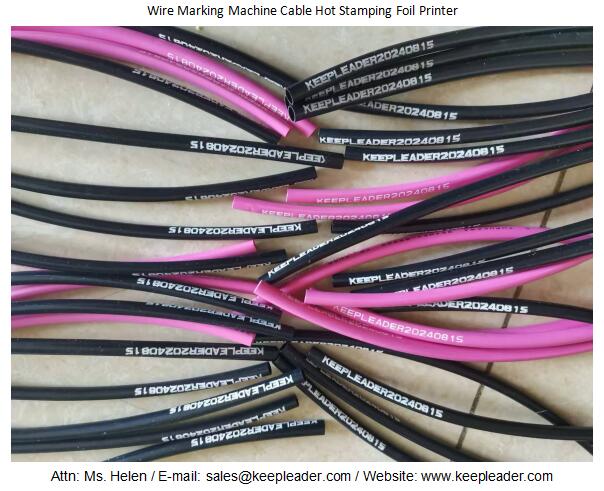

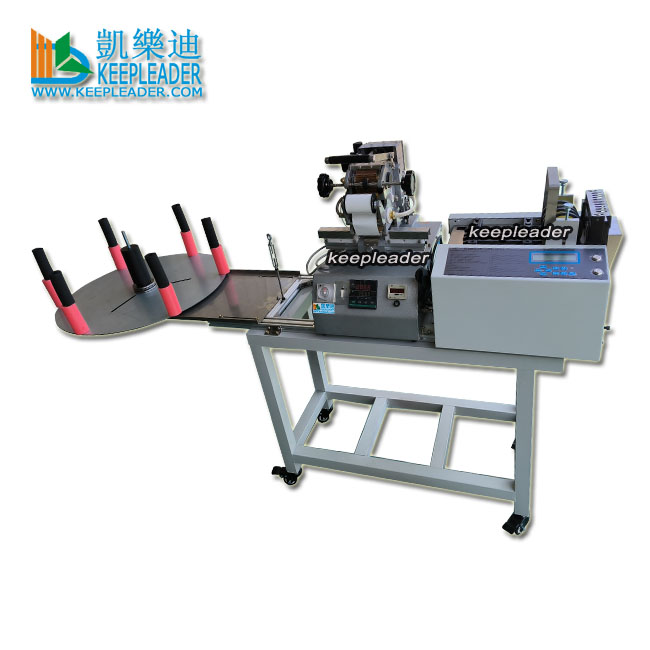

Wire Marking Machine Cable Hot Stamping Foil Printer creates prints on the wire/cable’s insulation jacket by pressing a heated copper numbering wheel and pigment onto it, this pressed type deforms the insulation jacket and causes engravings, while the pigment adheres to the insulation jacket due to heat, the pressing press is conducted by air cylinder or motor, because of computerized cutting unit and auto roll feeding mechanism are integrated, hence, this Wire Marking Machine Cable Hot Stamping Foil Printer can achieve auto printing and cutting in line, the printable materials include plastic molded products, such as bundling bands and connectors, control cable, shrinking sleeve, medical tube and electric wires and relative sheath, furthermore, changing the print color in hot foil printing unit can be easily accomplished by replacing the pigment foil, moreover, no drying time is required, since liquid link or organic solvent are not used in this dry-link printing approach

Machine Description

Wire Marking Machine Cable Hot Stamping Foil Printer

Application

Wire Marking Machine Cable Hot Stamping Foil Printer can execute automatic cutting and printing in line in wire/cable coding/marking/decoration process, the wires feeding in roll enter into hot foil stamping unit, where create prints on the insulation jacket by pressing a heated metal type and pigment onto it, this pressed type deforms the wire rubber and causes engravings, while the pigment adheres to the wire jacket due to heat, after done, the wire continuous go through the computerized cutting unit, where, motorized drawing mechanism align the selected combination of cutting and printing length, reach this point, the user can obtain the printed cutting length of expectation in addition, this Wire Marking Machine Cable Hot Stamping Foil Printer can operate separately, the hot foil printing unit has whole printing function, that can trigger with a hoot pedal, or it can be connected to a cutter unit, or strip unit, the existing interface allows the connection to products by different manufacturers, wire straightener, foil rewinding system and wheel lock are add-ons allowing for large series production, the cutting unit takes the same individual function for cutting length at interval space separately

Parameter

Name | |

Model | KLS-1824C |

Material | Wire/cable/tube/shrinking sleeve/Sheath |

Power Supply | 220v, 50hz single phase |

Heating Power | 300w |

Cutting/Drawing Power | 500w |

Qty of Rotary Discs | 18pcs |

Max Numbers of wheels | 38pcs |

Character qty per wheel | 40pcs |

Characters in vertical | A~Z,0~9, ./- and Blank |

Character Long | 18 characters long |

Characters interval space | 1~1.5mm |

Concave depth | 0.75mm |

Interval Space of Cutting | 0.1~999m |

Stamping Pressure | 0~0.6Mpa |

Consumption | Pigment Foil |

Type Size | Horizontal: within 3mm, Vertical: 1.2 and 1.6mm |

Cable/Wire Diameter | 1.5~20mm |

Spare Component | Cutting Blade, Heating Resistor and Tension spring |

Controlling Software | Computerized Setting, monitoring and query |

Function | Wire/cable/tube/sleeve coding, and interval cutting as set rate |

Driving mechanism | Pneumatic stamping and motoring feeding system |

Stamping Temperature | 0~200 Celsius Degree / adjustable |

Stamping Time | 0.1~3 seconds |

Dialing Approach | Manual sliding gearing selector |

Heating-up Time | 2~4 minutes |

Conformity | Complied with All CE and EMC equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility |

Notable proposal | Wire samples be submitted in cases where there is doubt as to the processing capabilities of a particular machine |

Dimension | 1800*700*1200mm |

Weight | 138kgs |

Salient Character

Wire length cutting and identification cutting are completed in one machine

The characters around rotary discs can be changed quickly with the index system

All alphanumeric characters engraved in specified quantities of rotary discs

Single line type holder and scrap foil rewind, and pigment foil spindle are built in

Stamping temperature, pressure, dwell time and stroke distance all are adjustable

Computerized control, setting and monitoring cutting and feeding mechanism

Capable for marking, cutting on a wide variety of insulation types and sizes

Plunging distance of stamping head is adjustable for maximum production

Closed loop integral temperature controller for equivalent heating distribution

Automatic feeding, printing and cutting length of wires/cable/tube/sheath/sleeve

Printing horizontally or vertically are acceptable basin on limited rate of wires’ diameter

Wire Marking Machine Cable Hot Stamping Foil Printer

Detailed Images

Wire Marking Machine Cable Hot Stamping Foil Printer integrates foil printing and length cutting in an automatic roll feeding line, which can efficiently improve the productivity, its hot foil stamping unit is the oldest and most inexpensive method for wire identification, this method produces very durable and legible marking and can be used on both soft and hard insulation jacket of wire/cable, medical tubes, protective sheath, as wire is automatically pulled through a wire guide, a marking foil is placed between the wire insulation and heated numbering wheels, a pneumatic cylinder then presses the character wheels against the foil, which consist of a backing and pigment that imprints engraved characters on the wire insulation, producing the best quality mark requires the correct foil, wheel temperature, pressure and dwell time, pressure is a measure of how hard the character wheel presses against the wire, dwell time is the length of time the character wheel contact the wire, furthermore, the drawing force is generated in computerized cutting unit, there is aligning sensor to detect the feeding length to complete the selected cutting length basing on aligned printing position

Machine Uses

Wire Marking Machine Cable Hot Stamping Foil Printer has salient advantages of main aspects, such as long-lasting print: since the material is deformed and engraved in the shape of the typeface in hot foil stamping printer, the printing remains recognizable, even if the color peels off afterward because of the bumps and dents caused by the engraving; color variety: the marking foils for Wire Marking Machine Cable Hot Stamping Foil Printer is available in a wide variety of colors to contrast with backing insulation; operating cost: the major costs associated with Wire Marking Machine Cable Hot Stamping Foil Printer pertains to electricity and marking foils, therefore, the relatively inexpensive cost of marking foils and low power consumption with regard to hot foil stamping printers make them cost competitive against ink-jet and laser printers, both of which use high-cost inks; flexibility: Wire Marking Machine Cable Hot Stamping Foil Printer can combine the stripping, printing, cutting process in a production line for automatic production, meantime, the user can operate each functional unit separately

Contact Us

Wire Marking Machine Cable Hot Stamping Foil Printer can answer your fundamental questions on industry challenges of wire coding, what ink-based printing technology will have the dry printing to prevent smudging or transferring? What are my options for technology that produces a consistent, legible mark and length cutting simultaneously? Can i reduce scrape wires due to incorrect coding or low-quality marks in continuous production line, keepleader, we understand the specific needs for marking and coding in the wire, cable and flexible tubing industries, even in continuous process of printing, length cutting and stripping, our customization in configuration, operation, and dimension can gratify versatile wire coding scenarios, now, consult with expertise to verify more

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader