PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine of Plastic Corrugated Boxes Point Bonding Assembler

PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine

PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine is professional spot bonding equipment, is standalone cantilever structure, which is designed exclusively for points fusion polypropylene coroflute stacked sheets in assembling versatile sizes of PP corrugated boxes/containers/totes, its working principles still lies in advanced ultrasonic friction tech in polymer localized heating by high frequency wave in converting to mechanical vibration, which can deliver clean, strong and precise welds without the adoptions of adhesive, staples, screws, and fasteners, this technology ensure efficient bonding, maintaining the structural integrity and appearance of material, hence, the aesthetic and practical performance both are reliable, such as high efficiency: fast welding process with minimal setup time without downtime, the ultrasonic spot welding process is generally quicker that traditional heat pressure welding approaches; strong weld joints: produce strong, durable welds that are resistant to environmental stresses, providing structural integrity to the corrugated boxes because of molecular integration; low maintenance: ultrasonic spot welding machine typically has fewer moving parts compared to other welding methods, leading to lower maintenance needs and low service life; reduced labor costs: automation and ease of use can reduce the need for manual labour, cutting down on labor costs and increasing production efficiency

Machine Description

PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine

01: Application

PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine is specialized ultrasonic spot welder, which is configured with cantilever frame to apply vertical spot welding and suspended clamping pressure in versatile sized profile containers making, its principle is basic criteria of ultrasonic tech, that uses high frequency ultrasonic vibrations to melt and fuse polypropylene corrugated plastic sheets together, creating a strong and seamless bond without the need for adhesives or fasteners, this approach is widely used in various industries for packaging and manufacturing processes, we have specified tooling kits for our PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine, that can complete single point, or multiple points fusion at a cycle time, the quantities of bonding points, pattern and shape are fixed selection, but, its welding thickness is adjustable, the completed PP corrugated boxes has wide applications, such as automotive sector PP box, coroplast corrugated box, corrugated box, food and beverages container, industrial storage container, pharmaceutical storage,retail packaging, Plastic basket, corrugated board, universal board, double wall board, folding hollow board turnover box, etc keepleader, we tailor PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine, which combines cutting-edge technology with user-centrism design and providing a reliable and efficient solution for you welding needs, whether you are looking to streamline your production process or enhancing the quality of your products, our ultrasonic spot welding machine offers the performance and versatility you need

02: Attributes

Name | PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine |

Application | Plastic Basket,corrugated board;universal board,Double Wall Board, Folding Hollow Board Turnover Box and etc |

Model | KLC-2015L/KLC-3215L |

Electric Connection | 220V,50HZ or 110v, 60hz Single Phase |

Ultrasonic Frequency | 15khz |

Ultrasonic Horn | Made by Aluminum or Titanium |

Ultrasonic Power | 2600w/3200w |

Productivity | 700 to 1200 pcs / hour |

Air Pressure | 0.4Mpa to 0.6Mpa |

Rack Structure | Cantilever Structure Square Column |

Driving Mode | Pneumatic |

Diameter of Prolonged Horn | 14~18mm Optional |

Maximum Holding Height | 1000mm |

Maximum Suspending Depth | 1000mm |

Stroke Distance | 75mm |

Timer of Welding/Delay/Dwell | 0.1-99.99s |

Output Current | 0~100A |

Welding Length | Within 250mm |

Dimension | 1.1*0.8*2.2m |

Packaging Dimension | 1.2*1.0*2.5m |

Net Weight | 280kgs |

Gross Weight | 338kgs |

03: Salient Advantages

PLC controlled microcomputer control systems,which is accessible for precision setting

Ultrasonic horn is adjustable for its balance, up and down travelling distance

Cantilever frame and deep beam for versatile loading processes of height and depth

Robust fuselage to apply reliable and consistent pressure without backward tilt

Precision melting control to improve stunning welds and prominent bonding strength

Auto-tuning system of ultrasonic frequency between ultrasonic generator and acoustic tool

Adaptability is excellent by replacing ultrasonic tooling kits for versatile sizes in construction

Capable of high speed welding to increase production efficiency

Highly durability of strong bonding is resulted from parameter monitoring and self-tuning

Digital control panels for precision adjustment of welding parameters, such as time, pressure

Ability to adjust welding for different thickness of PP corrugated sheets

Emergency stp bottoms, protective covers and sensors to ensure safe operation

Acceptance is wide in production of PP Corrugated boxes, trays partitions and totes

Fusion is strong and faultless that ensure the integrity of box assembly by ultrasonic vibration

Customized acoustic tool is specified for Individualism, such as welding thickness and material

Space-saving design is suitable for a range of manufacturing application

Eliminating manual labor and increasing overall production efficiency

The accuracy and uniformity are guaranteed by enhanced quality control system

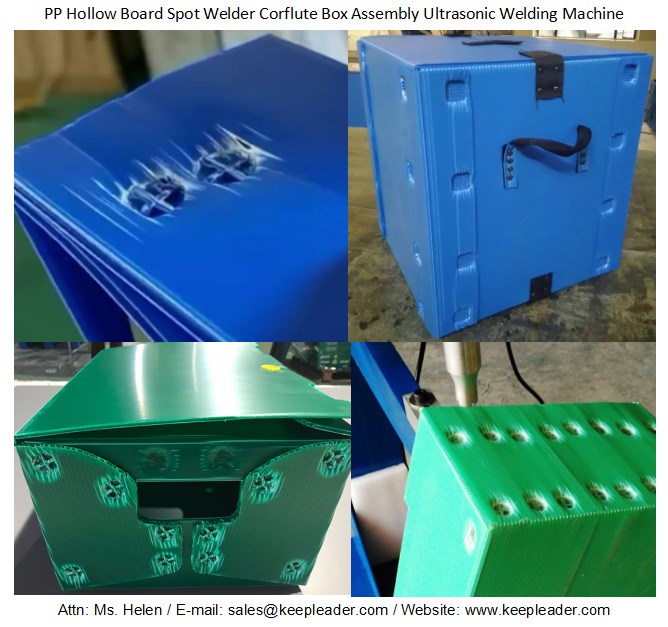

Detailed Images

PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine is specially developed by keepleader for manufacturing PP Corrugated boxes, the cantilever structure of fuselage has deep beam, which can suspend the stacked corrugated sheets in working position whatever height and depth are acceptable within 1000mm, or specified limit, this standalone ultrasonic spot welding machine can weld one or two laminated PP corrugated sheets together, which makes it production-friendly, keepleader can design the frame of the machine as per customer specification, like multi-head fixed or movable, the new new frame developed by keepleader is very robust and user-friendly, the ultrasonic system used in this PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine has already been proven, all components used in this ultrasonic PP Corrugated box welders are international class

Machine Uses

PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine prevails in PP Corrugated boxes packaging field, which is reliable and sustainable solution in points fusion process because of market’s corroboration, likely high quality finished PP Corrugated boxes with tight seals and strong joints; reduces costs and eliminates the need for consumables;minimal waste and does not involve the user of glues or solvents, resulting in a clean and environmentally friendly process; this PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine can weld PP corrugated boxes of various sizes and shapes, the operator is maneuverable in alignment and commissioning; the welded joints are resistant to tearing, moisture, and heat-resistant

Contact Us

PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine is a high-speed efficient machine used to weld corrugated plastic boxes, it uses ultrasonic technology to create a strong, seamless bond between the different layers of the corrugated plastic sheets, resulting in a sturdy and durable packaging solution, this ultrasonic spot welding machine is widely used in variety of industries, including food, pharmaceutical and automotive, for packaging and storage purposes, it can also be used to create custom packaging solution for a variety of products, the PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine is a reliable and cost-effective solution for companies looking to improve their packaging process in PP Corrugated boards assembly, Our PP Hollow Board Spot Welder Corflute Box Assembly Ultrasonic Welding Machine combines cutting-edge technology with user-original design, providing a reliable and efficient solution for your welding needs in assembling corrugated boxes/containers, whether you are looking to streamline you production process or enhance the quality of your products, our ultrasonic spot welding machine offers the performance and versatility you need

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader