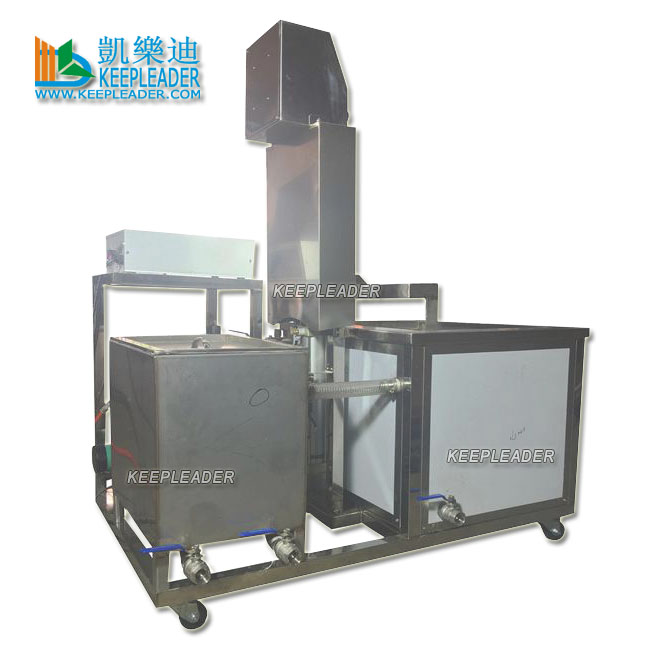

PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift of Auto_Engine Parts_Cylinder_Carburetors Cleaning Machine

PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift

PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift sorts to immersion washing with ultrasonic agitation built in motor driven auto lifting device, this industrial washer achieve fast, economical and efficient cleaning performance in removing dirty, oil, grease, flux, soldering agent,fingerprint, oxide film and other contaminants from visible and invisible surface, the cleaning object immersed inside tank of ultrasonic cleaner becomes a sound wave conductor and helps clean itself, most intricate parts may be cleaner without disassembly, the cleaning efficiency of this method is not duplicated by any other available means, ultrasonic cleaning is the application of a high frequency sound wave to an aqueous solution or solvent, the introduction of this sound wave into cleaning solution creates millions of microscopic bubbles, which expand and collapse, implode vigorously, the agitation produced by the formation and implosion of these tiny bubbles effects an intense scrubbing action submerged parts in the cleaning tank and remove accumulations and residues, additional, ancillary lifting up and down stirs the liquid in uniforming direction of penetrate any nook and cranny, timely take apart dislodged debris and particles deeply inside of blind holes, cracks, crevices and any inaccessible corners

Machine Description

PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift

01:Application

PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift combines ultrasonic wave stirring and auto lifting agitation to remove oil, grime, dirty, dust, grease,wax,polishing agent and other contamination on the surface or any nook and cranny of metal,plastic, rubber, ceramic object, such as all types of engine parts, automotive part, filter, muffler, coalescer,manifold, carburetor and etc,

PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift is an exceptional technique that facilities the cleaning process, it is exceptionally thorough process which cleans efficiently various items, this powerful process can perform very detailed work quickly and successfully remove microscopic particles from hard surface, external as well as internal surface, blind holes and crevices, can be cleaned simultaneously and uniformly, grease, oily and sticky parts are efficiently cleaned

The applicable varieties include automotive: thoroughly removes carbon deposits, grease, and other type of dirty and contaminants from carburetors, exhaust manifolds, cylinder block, motorcycle engines snow machine, ATV Cylinder and heads and more, marine: suitable for inboard and outboard motors, aircraft: thoroughly can safely clean both large and small parts, turbine blades, fuel nozzles, generator components, brakes and other parts that require periodic cleaning

02:Parameter

Name | PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift |

Model | KLE-1052AL |

Power Supply | 280v,50hz |

Internal size of cleaning tank | 800*600*600 |

Thanks Volume | 288L |

Vibrating Spectrum | 316L,Chromium Coated of Stainless steel: 2mm |

Ultrasonic Power | 2600w |

Heating Power | 4kw |

Ultrasonic Vibrators | 50w, qty:52pcs |

Timer | 1~99min Adjustable |

Heater | 0~80 Celsius |

Frequency | 28hz/40khz |

Timer | 1~30 Minutes Preset |

Material | Stainless steel 304/316L |

Lifting Actuator | Motor/Pneumatic Driven |

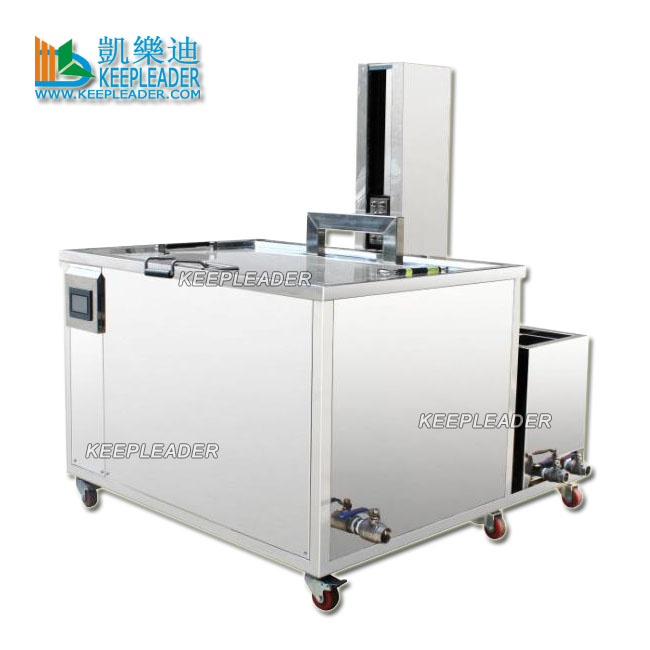

Control | Programmable Logic Control with Touch Screen |

Operation type | Auto lifted platform agitation |

Drain Valve | One Inch |

Movement | Qty:4 caster of 2 with brake |

Power Control | 40%~80% |

Weight | 500kgs |

Overall Size | 1200*1200*1500mm |

Packaging Size | 1300*1300*1800mm |

03: Ancillary function

PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift benefits from its built-in features, optional ancillary elements following are listed for your reference in ultimate caparison

031: Degas mode speeds solution preparation: freshly prepared ultrasonic cleaning solutions contain entrained air that inhibits cavitation, trapped air can be removed via two channels, letting the ultrasonic cleaner operates for a period of time without a load or specifying a ultrasonic cleaner with a degas mode for faster results, a degas mode does this jobs be switching on and off causing air bubbles to coalesce, rise to the surface and burst, this benefit of a degas model increases with the cleaning solution capacity of the ultrasonic cleaner’s tank

032: The benefits of the sweep mode: frequency sweeping provides a slight fluctuation in the PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift and serves to even out the cleaning action, this avoids what we called “hot spots” or more intense and possibly damaging cavitation action, “dead zones” or no cleaning action, and harmonic vibrations that can damage delicate parts such as PCBs

033: The pulse mode boosts ultrasonic power: if you are cleaning products with particularly tenacious contaminants specify an PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift with a pulse mode, pulse mode boosts ultrasonic power to 20% to remove stubborn contaminants, the ultrasonic performance is temporarily increased while even ultrasonic sound field distribution in the bath enhances the cleaning effect

034: equivalent comparison in ultrasonic power output: when an PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift is running, electrical power is consumed evenly but it is released in intervals to create the sound waves that shape the ultrasonic signal, ultrasonic power output varies peak power from average power, when comparing a ultrasonic cleaner you must compare based on the same criterion

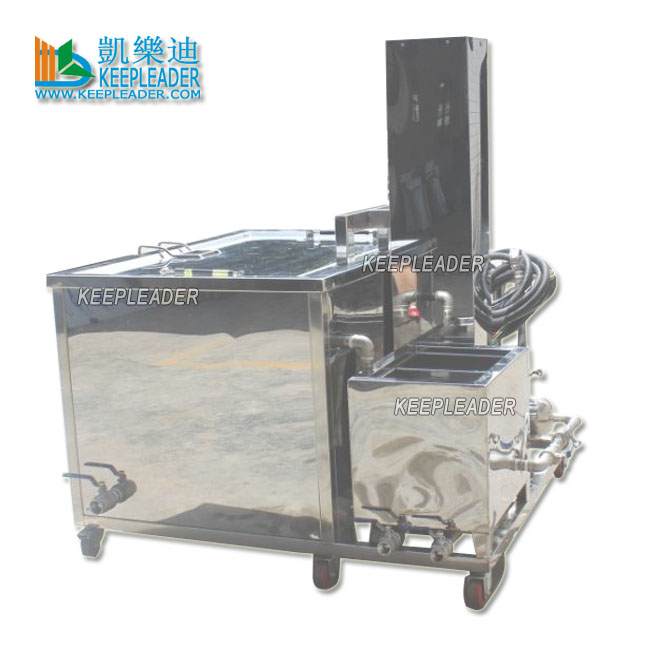

04:Characters

High frequency ultrasonic generators and transducers in combination to achieve reliable performance in ultrasonic cavitation and implosion

Compact structure, simplified operation and robust construction and solid-state design

Built-in alarming system of indicating liquid low level, cleaning parts loading and unloading

Programmable Logic control with touch screen to operate visually and digital control

Presetting Timer, temperature, ultrasonic intensity, and lifting speed

Dual cartridge filtration with cotton core of filtrating particles 5um and over fill protection

Oil skimmer to timely remove the dislodged grease to avoid cross contamination

Forklift base for easy transportation, caster with brake is convenient to more and stop

Aluminum board heating element to assist on equivalent and consistent thermal-stat

Automatic frequency tuning of ultrasonic generator to keep prominent performing

Motor driven auto lifting device integrates with ultrasonic soaking tank for uniform agitation

High Q ultrasonic transducers, high strength glue bonding with screw fixing for efficient transmission and guaranteed longevity

Tank body made of SUS304 of 2.0~2.5mm,the vibrating spectrum is plated with environmental protection chromium treatment

05:maintenance

Kindly follow the below content directory to maintain your PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift, it will serve your longer

Install in ventilated and dry place in your working shop

Keep ultrasonic cleaner away from heat sources,leave away from flammable material

Avoid splashing liquid into the electric cabinet and surface of inside vibrators

Keep the machine clean and turn off the power when it is not in use

Avoid violent collisions, happen impact often damage the uniformity

Timely precipitation, filtration or replacement of cleaning fluid

Remove the sediment in the tank in time, improve the tank durability

Regularly clean the dust attached to the electric cabinet and vents with compressed air

Regularly test the insulation of the equipment, check the ground wire

Regularly confirm power supply compliance

Regularly replace the circulation and filtration system’s filter element

When the machine is not in use, empty the solution and clean the inner tank

When the equipment is not in use, turn it on once a month, let is run for 30 minutes

Detailed Images

PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift obtains salient advantages in functionality and configuration below

Circulation and filtering system: it consists of corrosive--resistant magnetic pump and filtering element, the filtering cotton core quickly separates the dirt and clears up floats on the liquid surface, at the same time, it accelerates electrolysis and purifies the solution, complete the function of filtering the dust, oil, was, rust and burrs in the liquid and reduce cleaning fluid replacement frequency, avoid secondary pollution of parts, achieve te best cleaning effect, save cleaning fluid and cleaning agent, reduce cleaning costs and eco-friendly and energy saving, the factories are focusing on environmental protection now and circulation and filtration system will become more and more popular; pulse mode: stimulate higher energy cavitation effect, blow away more stubborn pollutants; degas mode: remove the air in the fresh cleaning solution, ensuring a better cavitation effect without air interference, quite suitable for large-capacity industry ultrasonic cleaner; lifting platform: put the cleaning basket on the lifting platform, the platform automatically raises or lowers the cleaning basket, it is convenient and fast, saving the operator’s energy, this lifting platform additionally accomplish up and down agitation during ultrasonic cleaning process for speeding up the dirt decomposition

Machine Uses

PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift

Buying Guidance

Troubleshooting of PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift process

How to use ultrasonic cleaning machine correctly and efficiently, there are many professional suggestions collected from KEEPLEADER’S training course, herein, hope this post can acknowledge more companies, who are using ultrasonic cleaning in their production process

01: In first shift working, our ultrasonic cleaning machine works not so expected, why is this so?

Ans: everyone clearly knows that ultrasonic cleaning must use aqueous media or chemical solution, this possibility of dissolved gases hided, in ultrasonic process, as high-frequency sound waves travel through aqueous media, areas of compression and rarefaction occur, during rarefaction, there is negative pressure, with enough loudness (sufficient amplitude), cavitation, voids or tear in the cleaning liquid occur, these are sometimes referred as cavitation or vacuum bubbles, when the bubbles collapse or implode during compression, the energy (pressure and localized temperature) associated with this collapse is responsible for the cleaning power of ultrasonic

In the first shift cleaning, it is a near certainty that the aqueous media contains dissolved gases, this means that the ultrasonic bubbles formed during rarefaction contain dissolved gases rather that a near-vacuum, the bubbles are “cushy”, so they do not collapse efficiency, turning on the ultrasonic for a few minutes prior to processing a product releases the dissolved gases, if the ultrasonic machines have not been used for a whole, you should degas cleaning chemistries, or if fresh cleaning chemistry has been added, if in doubt, then degas

02: We have a small unheated ultrasonic tank, as the day goes on, cleaning efficiency keeps getting better, is this all due to degassing?

Ans: Most of the improvement is probably due to temperature effects, in fact, as the day progresses, the ultrasonic transducers generate heat, causing the temperature in the ultrasonic tank to increase, unless a temperature-controlled system is used, as the temperature increase, ultrasonic cleaning performance tents to improve, up to a point, the maximum performance temperature depends on the cleaning chemistry, for water, the maximum temperature about 55 degree, as the temperature increase, the viscosity of cleaning chemistry decreases, so cavitation becomes increasing effect, in addition, as the temperature increases, cleaning effectiveness tents to increase, whether or not ultrasonic are used

03: Why does ultrasonic performance decline later in the day?

Ans: When the liquid reach its boiling point caused by heating and inherent ultrasonic produced, for reason related to the degassing issue, the higher temperature, the higher the vapor pressure of the liquid, so the cavitation bubbles has more vapor, the bubbles become “cushy” and they do not implode effectively

04: The effectiveness of our ultrasonic cleaning line seems to vary throughout the day, why do we notice the worst problems when our throughout is highest?

Ans: The tank size usually design its average cleaning volume, if the cleaning basket is overloaded, the ultrasonic energy cannot reach any corner because of ultrasonic intensity is dampened during travelling ,

05: How to choose correct ultrasonic frequency?

Ans: For small components and precision parts, KEEPLEADER suggest 40khg or bigger, the higher frequency, the bubbles is smaller, which can have good penetrating performance into tiny blind holds, recesses, cracks, and gentle ultrasonic rubbing force, can well protect the substrate of cleaning parts, but the smaller bubbles cannot contain higher temperature and pressure, so, for big size parts or heavy grease, 28khz play a good cleaning role, up to one point, this depends on the your current and anticipated production line and process requirements

06: Our parts have heavy grease, we toss parts into the ultrasonic tank, leave them there for hours, How long do we need to clean them?

Ans: Ultrasonic cleaning time usually set in minutes, 3 to 5 minutes is normal, but, tank normally heated or chemical added to reduce the water surface tension and improve the bubble forming, many factories also using spraying process to speed up the cleaning, anyhow, the cleaning time is not hours, if have somehow, the chemical added might not be optimal, you need to adjust the change it, or ultrasonic transducer might be malfunctioning, the placement of the transducer or power density might be incorrect for the task at hand, the parts might not be suspended properly, so that parts are shadowed

07: If plastic tank, basket or fixture is ok for ultrasonic cleaning system?

Usually, no plastic in ultrasonic cleaning should be better, as mentioned previous, ultrasonic contains pressure and hot energy in vacuum bubbles, which implode when touching the substrate of cleaning parts, plastic tank, basket or fixture can soften and dampen the suction force, so, stainless steel, metal basket is recommended, we notice that some companies toss their parts into the plastic tank with ultrasonic vibrations in testing and erroneously concludes that their tank is workable, so not that, KEEPLEADER also advise you to consider your mesh size, try to use big mesh size in solid stance

08: Can we use acetone in ultrasonic cleaning for small-scale?

Inflammable solvent is strongly forbidden in ultrasonic cleaning, acetone is over its flash point at ambient temperature, ultrasonic is ignition source, most of ultrasonic cleaning machine is designed for organic, non-inflammable solvent cleaning

09: Conclusions

Efficient ultrasonic cleaning depends on its cleaning quality and productivity, for ordering, you need to evaluate what ultrasonic cleaning system can do, even the most important is what cannot do, take a step back, look at your whole cleaning line, where need to be improved and changed

Contact Us

PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift belongs to our standing-along aqueous immersion cleaning ultrasonic cleaner combined with auto lifting agitation, equipped circulation and filtering system that is proven to be a reliable washing tank in removing grease, oil, wax, oxide film, carbon deposit, flux agent, dust, rust, grime, particular residues and polishing powder, keepleader, we research, develop, and construct aqueous cleaning ultrasonic cleaner over years of decades,we can provide everything you need, for small stainless steel tanks to automated modular system, ask about our PLC Control Automatic Ultrasonic Cleaner With Hydraulic Platform Lift,or how we can build a tailored ultrasonic cleaner for your company using a range of frequencies to tackle your specific needs, our ultrasonic cleaner technology and transducer applications, along with our world-class engineering expertise in stainless steel construction and cavitation cleaning advantages, allow us to meet virtually any need you must have along your manufacturing line, our technique experts are always ready for further assistance

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader