Diesel Engine Parts Ultrasonic Cleaning Machine for Oil_Grease Degreasing Washer Particle_Powder Removing 28k Ultrasound Cleaner

Diesel Engine Parts Ultrasonic Cleaning Machine

Diesel Engine Parts Ultrasonic Cleaning Machine is single soaking chamber with ultrasonic agitation, at where the cleaning procedures arranged all in one tank of pre-soaking, ultrasonic agitation cleaning, and post-rinsing, ultrasonic generator convert electric current to ultrasonic signal, transducers mounted at the beneath of ultrasonic tank as vibration spectrum received ultrasonic signal to produce sound wave, which in turn, creates cavitation bubbles that scrub the engine parts, the bubbles form and collapse rapidly along the surface, also penetrates small crevice and passageway, particularly for hand-inaccessible area, as the bubble implode, they pull dirty and particles away from the engine parts, and up to the top of the liquid, our engine parts ultrasonic cleaner adopts frequency 28khz to work well with engine components in resonant wave, bust sufficient scrubbing force such as cylinder heads, and blocks to get the expected cleaning effect

Product description

| Application | ||

| Diesel Engine Parts Ultrasonic Cleaning Machine do Cleaning for Motor, Car engine and peripheral engine parts, and other metal parts in need of removeing oil, Polishing wax, dust and etc | ||

| Character | ||

Auto frequency tracking function, which have advantage of automatic find the best ultrasonic performance for different cleaning parts This machine can connect with remote control All in one machine, Compacted design, which is easy operation The machine has special access to do maintenance Low voltage operation penal for safe operation | ||

| Detailed Parameter | ||

| Name | ||

| Model | KLE-10180 | |

| Vibrators | 180pcs | |

| Auxiliary | Cleaning basket and heating | |

| Ultrasonic power | 10800KW | |

| Heating power | No | |

| Vibrator standard | 28khz/40khz,50W/60w/pc (optional) | |

| Power supply | 380V/220V,50HZ/60HZ (optional) | |

| Size of inner cleaning tank | 1500*800*1000mm(L*W*H) | |

| Size of outside | 1600*900*1200mm | |

| Capacity | 1200L (1100L is available) | |

| Control mode | Mechanical | |

| Heating temperature | No | |

| Vibration mode | Side vibration | |

| Heating mode | No heating | |

| Cleaning basket | Stainless steel, the mesh over 10*10mm | |

| Switch | Separated Power Switch, Ultrasonic SW and Heating SW | |

| Configuration | Assembled Four Universal wheel | |

| Separated lid/Cap | ||

| With cleaning Basket | ||

| Each generator has power wire of 5m | ||

| High Q value(NTK made in Japan) Vibrators | ||

| Stainless steel Drain valve assembled under the bottom | ||

| Automatic frequency tracking Generator | ||

| Over-current protection | ||

| Soft-start function | ||

| Material | ||

| Inner cleaning tank | SUS304L,2.0mm | |

| Vibrating side | SUS 304L,2.5mm | |

| Surrounded outside | SUS 304L,1.0mm | |

| Base support | Stainless steel Square tube 38mmx38mm,1.5mm | |

| DC Connector | no, low voltage power connection | |

| Process standard | ||

| Vibration side | Hard chrome plated over 0.05mm | |

| Appearance | No glitches, no corners, smooth, beautiful | |

| Inner cleaning tank | Well welded, upright, water-proof | |

| Welding spot | No burn marks, welding marks after polishing | |

| Fixed screw | Ball head smooth | |

| Assembled mode of vibrator | Glued + Screwed | |

| Heating rod | Well insulated, short-cut protected | |

| Free spare parts | ||

| Separated generator, heating rod, fuse | ||

| Packing | ||

Wooden case with pallet, easy operated by fork Supported under the bottom avoid impacting during delivery Stretch seal around | ||

MFR: KEEPLEADER has modified and designed Engine cylinder head ultrasonic cleaning machine to accommodate our customers' unique and special requirements,

pls contact KEEPLEADER for tech assessment to make a proper solution

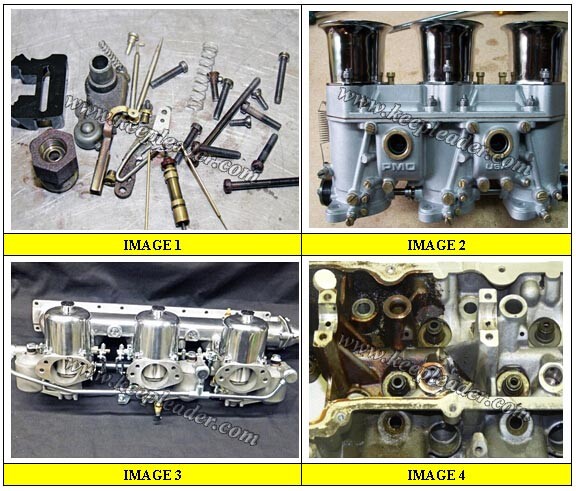

Detailed images

Diesel Engine Parts Ultrasonic Cleaning Machine adopts the universal principles of ultrasonic wave transmits into the liquid to produce tiny invisible bubbles, of them form, grow and collapse under the displacement of contraction and expansion, the great energy and temperature entrapped in this bubbles activate scrubbing force on the surface, also penetrate into the deep passageway, even the inaccessible crevice, crack and blind hole or unreachable corners of engine components, Our construction gets worthy investment, the controllable element in your prior consideration enters in the selection and commission, different cleaning solution will work well with your engine parts, these could range from alkaline solution,acidic formulations, DE-ionized water, mild alkaline solution, high-caustic or neutral chemicals, all you need is water and specific cleaning fluid to put into the tank, proper ultrasonic cleaning solution should be used for engine parts, oils that float on the surface of the ultrasonic tank should be skimmed off and disposed of properly, when the solution becomes discolored or takes longer to clean, it is time to replace the solution, drain the tank and dispose of the waste solution in accordance with local regulations, take the time to remove any sludge that has settled to the bottom of the tank, clean the tank using our recommended cleaning procedure, the prominent priority of solution for diesel engine parts includes properties in safety, the solution for metal should be safe, preferable with anti rust, effect, the cleaning fluid should remove both oxidation and dirt, formulation, the solution should remove gasoline residues, carbon deposits and grease, at any case, be careful, anything is caustic or contains sodium hydroxide will react with aluminum

Product uses

Diesel Engine Parts Ultrasonic Cleaning Machine gets a lot of applause in engine degreasing process and more variety of parts of quicker and effective removing contamination, reducing exposure of technicians to toxic chemicals and laborious manual cleaning, Diesel Engine Parts Ultrasonic Cleaning Machine has proved more effective that mechanical or chemical cleaning, while traditional parts cleaning systems only seem to clean exterior surface, ultrasonic cleaner used for engine parts cleaning can remove contamination in interior, such as crevice, crack, tiny slit gap slot, blind holes, passageway, unreachable corners, and other inaccessible area, particularly, in diesel engine parts cleaning, ultrasonic cleaner takes results of consistent effect, cost-saving, out-of-sight operation, in addition, the assembled diesel engine can immerse into the cleaning tank, which is crucial consideration in selecting the suitable solution

Contact Us

We welcome the opportunity to explain every last details and all of the options available in fact, and. won’t waste your time and ours, our goal is to educate our potentialcustomers and let them make an informed decision, please contact KEEPLEADER for more info of Diesel Engine Parts Ultrasonic Cleaning Machine

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader