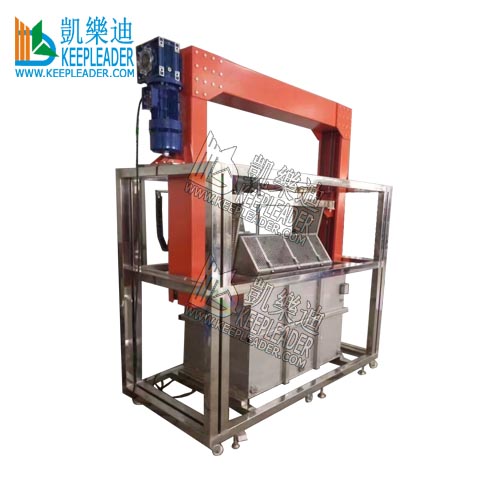

Rotary Drum Washing Tank Industrial Ultrasonic Cleaning Machine of Auto Lifting Device Rotating Basket Soak Ultrasound Cleaners

Rotary Drum Washing Tank Industrial Ultrasonic Cleaning Machine

Rotary Drum Washing Tank Industrial Ultrasonic Cleaning Machine is equipped with rotating drum which is suitable for cleaning small size of metal, plastic with heavy grease, the parts is too small, the ultrasonic agitation cannot penetrate inside, the rotary drum structure can solve this problem, the rotary cleaning drum can form a cleaning surface along the netted drum, the rotary force also can move away the heavy grease to get a better cleaning effect and improve the cleaning efficient, the auto elevator configured with spinning cleaning basket to exert up and down agitation, then the ultrasonic energy can transmit and distribute entire tank for consistent cleaning effect

Product description

Rotary Drum Washing Tank Industrial Ultrasonic Cleaning Machine

01: Parameter

Model | KLE-1048RL | KLE-1056RL | KLE-1080RL |

Ultrasonic power | 2400w | 2800w | 4000w |

Heating power | 8kw | 9kw | 12kw |

Lifting weight | 80kgs | 100kgs | 180kgs |

Lifting power | 2kw | 3kw | 5kw |

Ultrasonic frequency | 28khz/40khz | ||

Power Supply | 110v~380v/50hz/60hz | ||

Timer | 0~99 | ||

Tank volume | 280L | 338L | 480L |

Inner size | 800*600*600mm | 800*650*650mm | 1000*800*600mm |

Dimension | 1300*1000*1600 | 1300*1050*1700mm | 1500*1200*1600mm |

02: Application

Rotary basket ultrasonic cleaning machine is equipped with rotary cleaning basket and lifting system, which is suitable for hardware cleaning and any other small size of metal, plastic parts cleaning with heavy grease, because, the cleaning parts is small, the ultrasonic cannot well penetrate inside, the rotary basket can solve this problem, the Rotary cleaning basket can form a cleaning surface along the netted basket. The rotary force also can move away the heave grease to get a better cleaning effect and improve the cleaning efficiency, the lifting system can make the loading and unloading more convenient and save the elbow force and improve the cleaning efficiency, when the basket is rotary, the lifting system also has slow-pulling to generate a taking-force, if you want better cleaning effect for precision parts, KEEPLEADER also can mount circulation and filtering system

03: Cleaning procedures

Lifting basket is automatic up

Load the cleaning parts into the rotary basket

Lifting basket is automatic down into the cleaning tank

Ultrasonic cleaning starts when the basket is rotary

After several minutes, the lifting basket is up again

Unload the cleaning parts

04: Optional functions

Circulation and filtering unit

Hot air drying gun or hot air drying tank

Water-level detector and protection system

Multiple cleaning chambers for dirty cleaning, rinsing and drying procedures

05: Characters

The cleaning chamber equipped with rotary basket/round cleaning basket

All made of stainless steel,

Servo motor impelled rotary basket for all direction cleaning and take away the residue in time

Built-in timer, counter, temperature, rotary speed controller

Built with lifting system

Machine Uses

Rotary Drum Washing Tank Industrial Ultrasonic Cleaning Machine qualifies bulk cleaning of metal, plastic parts in small size, the rotary drum form a cleaning surface to activate impacting force of ultrasonic agitation, cleaning parts are loaded with platform in the upper position, the rotary drum is lowered with auto elevator, lid is closed manually, treatment is started by pressing the start button, after degreasing, the lid is opened manually, and the rotary drum is auto lifted to the top limit for ready unloading, because of auto elevator combined with rotary drum in ultrasonic agitating tank, this Rotary Drum Washing Tank Industrial Ultrasonic Cleaning Machine plays a reliable roles of metal and plastic parts cleaning in small size and batch scale, robust and safe lifting device, motor driven helix movement, ultrasonic transducers on two sides mounted, adjustable speed rotating drum and robust construction, all of these items keep it prominent in cleaning large quantities but small size

Detailed iamges

Rotary Drum Washing Tank Industrial Ultrasonic Cleaning Machine stands out of competitors in salient features of #1: motorized automatic lifting device: the integrated elevator takes lifting action during loading and unloading, also can be ancillary process in up and down agitation during rotating drum #2: Auto speed-controlled rotary drum: the rotary drum can improve the water impacting force with the surface of cleaning parts, and assist on penetrating into the deep corner, crevice, crack, bind holes, recesses and other water accessible area in small and middle size of cleaning parts #3: Top open door built in the rotary drum to quick access in loading prior to cleaning and unloading after cleaning, the rotary drum also can freely tumble for convenient feeding and discharging #4: high-quality piezoelectric crystals: our transducers are built with high quality ceramic crystals, which can expect 5 more years of use before the transducers begin to decay #5: self-tuning ultrasonic generators: ultrasonic generators adopted in this cleaning machine are self-tuning, which means they can sense the load of parts in the cleaning tank, and adjust power output based on the load, this also generators sense decay in a transducer, they increase power output so the parts receive the same level of ultrasonic cleaning as when the transducer was new #6: high-quality ultrasonic generator components are adopted in considering continuous working #7: No under-power ultrasonic transducer: ultrasonic transducers are measured by power output, but a more relevant measurement is watt density, measured as power per volume, we typically configure the ultrasonic cleaning system for 100 watts per 3.8 liters, this ensures that the ultrasonic energy is properly transmitted and distributed over the over the entire volume of the tank #8: thick-gauge stainless steel: our stainless steel ultrasonic tanks are built with thicker gauge of stainless steel that can withstand the long-term impact of ultrasonic vibration and, eroding

Contact Us

Rotary Drum Washing Tank Industrial Ultrasonic Cleaning Machine is designed and fabricated in-house, so keepleader, we have experts on on-hand to help you get the most out of your parts washing, modular units of each functional devices cover ultrasonic soaking tank, auto elevator, rotary drum, and programmable logic controller, which is optional ancillary combination in each individual production, we commit to fabricated bespoke ultrasonic cleaning machine without sacrificed quality, all of your concerns or initiation among our verification will be fulfilled, spend little more time on finding what unexpected items we can do for your production

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader