Ultrasonic Cleaning Kitchen Utensil Cookware Washing Machine for Dishes_Trays_Oven Racks Dip Soaking Tank Ultrasound Oil Cleaner

Ultrasonic Cleaning Kitchen Utensil Cookware Washing Machine

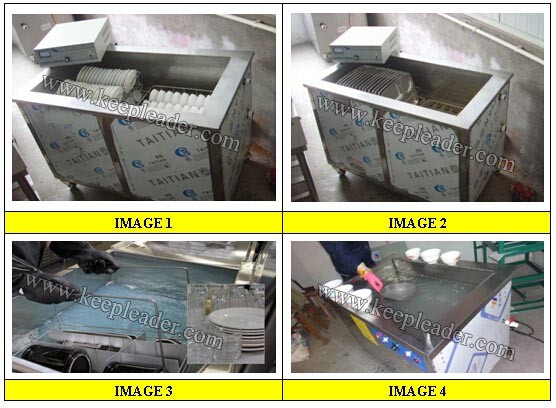

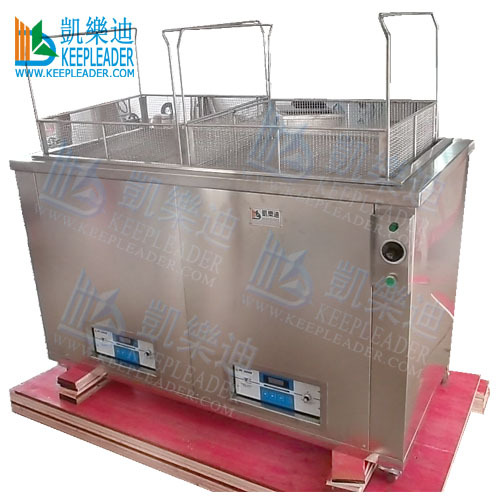

Ultrasonic Cleaning Kitchen Utensil Cookware Washing Machine is single dip soaking tank equipped into ultrasonic explosive jetting agitation applied in dishes/trays/bowls/oven racks in removing degreased oil/grease

Product description

Mainly application | |

Ultrasonic Cleaning Kitchen Utensil Cookware Washing Machine Applied for cookware ultrasonic cleaning, e.g: bowl ultrasonic cleaning and dish ultrasonic cleaning, any other dinnerware cleaning | |

Related field of ultrasonic cleaning technology ultrasonic cleaning of Semiconductor wafer, optical glass, clocks, beads | |

Character | |

All imported stainless steel structure, thickening Stainless steel plate, adopting high Q value transducer and German binding process large power of ultrasonic output, set solvent heating and temperature automatic thermostat instrument, and temperature control range 0~100℃, base solvent, no pollution Ultrasonic generator: VT model ultrasonic generator, output power continuously adjustable the basket design: one with two,the size and shape can be customized | |

With cavitations effect Ultrasonic cleaning technology is widely used in ultrasonic golf club cleaning, semi-conductor silicon chip cleaning, optical glass cleaning, parts of watch and cock cleaning, jewelry cleaning, polyester filtration core cleaning, widow blind cleaning and etc | |

Parameter | |

Model | KLE-1080 |

Freq | 28KHZ |

inner size (mm) | 1300*600*500mm |

The material of machine | Stainless steel 304 (outset cleaning tank) |

Stainless steel 312(inside cleaning tank) | |

Ultrasonic pwr | 4KW |

Heating pwr | 10KW |

Control | Digital control |

Cooling method | Fan cooling |

Heating time range | From 0s to 999s |

Temperature range | 0 to 100 degree |

Counter | Digital displayer |

Working mode | self excitation |

Vibrator assembled mode | Bottom or side |

Loading method | Manual |

MFR:KEEPLEADER has modified and designed Ultrasonic Cleaning Kitchen Utensil Cookware Washing Machine to accommodate our customers' unique and special requirements, pls contact KEEPLEADER for tech assessment to make a proper solution for your applicationUltrasonic Cleaning Kitchen Utensil Cookware Washing Machine

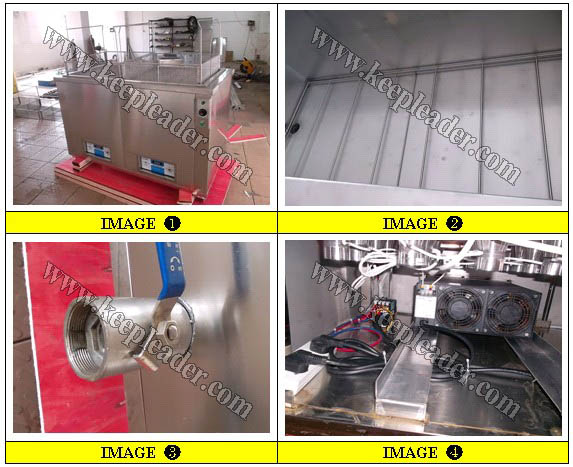

Detailed images

Ultrasonic Cleaning Kitchen Utensil Cookware Washing Machine is built-in features of #1: cleaning basket #2: basket suspended stop #3: quick drinage #4: enclosed cabinet of ultrasonic generators #5: screw bonded ultrasonic vibrators

Buying guides

Top 5 things to consider before choosing an ultrasonic cleaning machine

01; Size of parts/objects being cleaned

Always consider the largest item or part that will be cleaned regularly in the machine, full measurements of the largest item should be taken and given the manufacturer so that proper tank can be specified for the application

02: Ultrasonic cleaning goals

Post cleaning results are of primary concern for people in manufacturing, rebuilding, restoration or the medical field, ultrasonic is the most thorough process of cleaning known to science, consequently this methodology is utilized for countless application around the world today, this time to clean parts is greatly reduced when ultrasonic cleaners are used versus hand cleaning methods, as a result, production is dramatically increased while the cost of cleaning goes down

03: Utilizing the correct basket/racks

This items being cleaned must not touch the ultrasonic transducers located inside the tank, parts baskets should be utilized and selected specifically for the cleaning application, any parts or baskets making contact with the ultrasonic transducers packs will eventually cause the surface of the pack to etch or scratch, even though the packs are constructed of stainless steel, once etching occurs erosion will follow and will over time destroy the integrity of transducer pack, this damage cannot be repaired and transducer pack will eventually need replacement

Ultrasonic cleaners create heat energy as they run, the heat will rise during the cleaning process due to the friction of cavitations activity being created within the cleaning vessel, the rise in temperature cannot be avoid, heaters are required to bring the cleaning solution to the designed starting temperature, they are also a necessity when cleaning contaminants such as carbon oil and grease residue, high temperature help break down these contaminants to better facilitate the cleaning process

04: Generator adjustability and wave sweep

Wave sweep is utilized and recommended in virtually all cleaning situation, by dispersing various frequencies with different wave lengths, wave sweep effectively eliminates in active and deep zones in the cleaning tank, this results in more uniform and effective cleaning of all parts especially those of intricate detail, ultrasonic cleaners equipped with wave sweep do not require degassing modes as engaging the wave sweep accomplishes accelerated degassing of solutions

05:Ultrasonic frequency and power

Most ultrasonic cleaners operate between 28 and 120khzm, the lower frequencies produce large cavitations bubbles with more abrasive cleaning, these frequencies are recommended for coarse cleaning needs such as removal of lapping compounds from durable metal surfaces, for fine cleaning of very delicate items such as jewelry and soft metals with polished surfaces, higher frequencies may be more suitable, the most commonly utilized frequencies are 38 to 40khz because they are ideally suited for the vast majority of both commercial and industrial cleaning application, the power generated by an ultrasonic cleaner should be capable of dealing with the client’s most difficult cleaning applications, controls on the ultrasonic generator allow the operator to dial down the power whenever more delicate cleaning applications are addressed, because power can be dialed down there is no need to buy cleaner with minimal power capability, even cleaning delicate items may require more energy when multiple parts are cleaned at one time

For more that two decades, ultrasonic international has helped business improve profitability by providing their clients with ultrasonic cleaning equipment that feature the latest advancements in wave sweep technology, KEEPLEADER ultrasonic cleaning machine has a reputation for reliability and longevity utilizing the proper ultrasonic cleaning machine saves money and improves cleaning processes, cleaning results will be measurably better and less time and labor hours to complete the cleaning process, production mummers go up addressed simultaneously

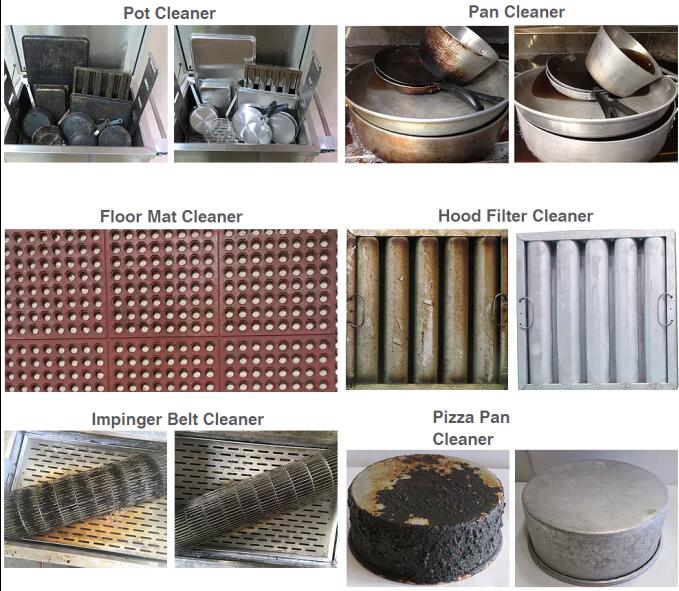

Product uses

Ultrasonic Cleaning Kitchen Utensil Cookware Washing Machine is applied for Kitchen utensil degreaing clean, for example: trays, bowls, dishes, Oven racks, and hood filters

Cleaning effect

Ultrasonic Cleaning Kitchen Utensil Cookware Washing Machine is added emulsified detergent in ultrasound wave explosive jetting agitation tank, molecular scales bubbles blast off stubborn oil, rust on the surface of cookware even into the blind holes, coners, and trapped into deep cracks, splits all hand or wipe cannot reach but water can immerse into

Packaging and shipment

Ultrasonic Cleaning Kitchen Utensil Cookware Washing Machine is safe plywood case in sea transportation and fumigation free

Contact Us

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader