Hot Air Drying Equipment for Industrial Ultrasonic Cleaning Machine of Single Tank_Electric Heat Sonic Cleaner Industrial Dryer

Hot Air Drying Equipment for Industrial Ultrasonic Cleaning Machine

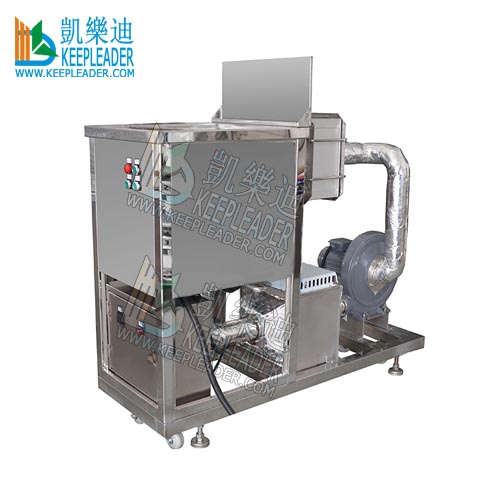

Drying parts after ultrasonic cleaning may or may not be required, if cleaning solution residues present no problem a drying step might be unnecessary, for example, the heat absorbed by parts during cleaning maybe sufficient to evaporate liquids, if rust is a concern after immersion in water-based cleaning solution, add a rust inhibitor for temporary protection, if cleaning solution residues are a concern the post-cleaning rinsing cycles are generally employed, these procedures can be as simple as moving the products to a fresh water rinsing station, when cleaning PCB, and other delicate electronic components a thorough rinsing with DI or distilled water is recommended yield a residue-free surface, when thoroughly dried are required before assembly, PCB for example, Hot Air Drying Equipment for Industrial Ultrasonic Cleaning Machine should be employed rather than replying on evaporation,parts with complex shapes can hold liquid in orifices and therefore should be subject to drying cycle, this type of drying equipment you use is governed primarily by the size of cleaning tank

Product description

Hot Air Drying Equipment for Industrial Ultrasonic Cleaning Machine

01: Parameter

Model | KLD-1018 |

Working mode | Hot air drying |

Inner size | 600*600*310mm |

Overall size | 1300*900*900mm |

Hanging couples | 560*560*290mm |

Drying parts | 540*540*320mm |

Power source | 380V±10% 50Hz |

Material | SUS304,2.0mm |

Drying temperature | 80~120 |

Rated power | 5.5kw |

Gross weight | 250kgs |

02: Application

Single tank hot air drying equipment is presented for drying of metal parts, Power board, glass, and other related components, usually coupled with ultrasonic cleaning machine, and panting surface baking, its rated temperature is usually set at 80~120 degree, KEEPLEADER™ also accept customized model for other special application

03: Drying cope

PCB drying after ultrasonic cleaning

Varnishing baking after painting

Metal, hardware drying after ultrasonic cleaning

Other special field in drying treatment

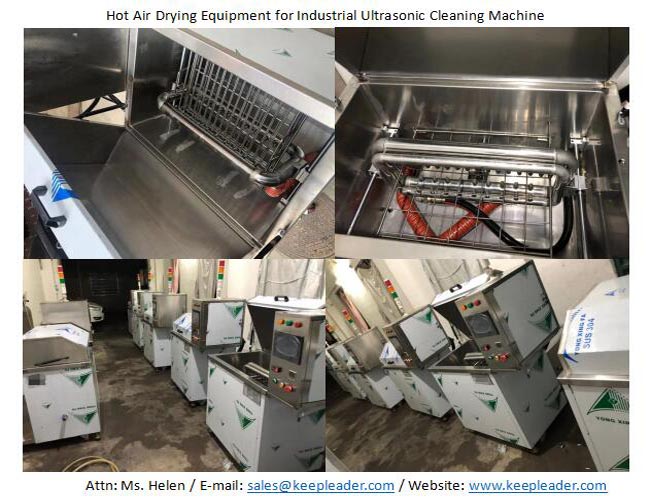

04: Character

Circling hot air to dry, quick temperature raised, and effectively reduces the heating time

Built-in air filtering system to avoid secondary contamination and improve the drying clearance

Tank top hinged with lid to reduce the temperature loss and drying performance

With drying alarm function to avoid overworking

Build-in liquid outlet at the tank beneath

Comes with hanging rack to load the drying parts conveniently

Detailed Images

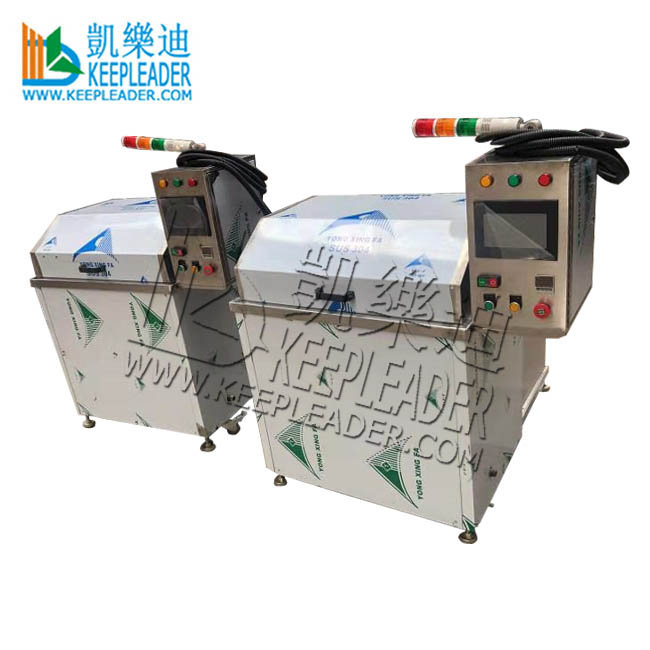

Hot Air Drying Equipment for Industrial Ultrasonic Cleaning Machine assorts to single tank hot air drier of free-standing combine with ultrasonic cleaning machine in organizing a completed cleaning procedures, especially, in multiple stages of cleaning process hot air drying tank is necessary to accomplish residue-free effect after rinsing, the quick dried cleaning parts proceed to next procedures, this free-standing hot air drying tank can freely arranged working sites and combine with your current or existed cleaning line, the consideration of its flexibility remains its popularity,the high pressure air blows the electric heating package, which generates hot air going trough the tube into the tank, the temperature and air speed are adjustable, so the loaded drying object in tank can quickly dried, keepleader, we can construct alcohol drying tank with movable hot-blast air nozzle at any angle to complete air drying at 360 degree, the program logic control is also built in with touch screen for convenient access in setting, reading,operating this drying equipment

Machine Uses

Hot Air Drying Equipment for Industrial Ultrasonic Cleaning Machine use a combintion of high heat and high air flow to dry parts after ultrasonic cleaning procedures, the thermostatically controlled temperature can be set between 60~90 degree, drying time is generally less than 10 minutes, depending on the number of cleaning pats, the temperature of the final rinse, and whether the dryer lid is in place

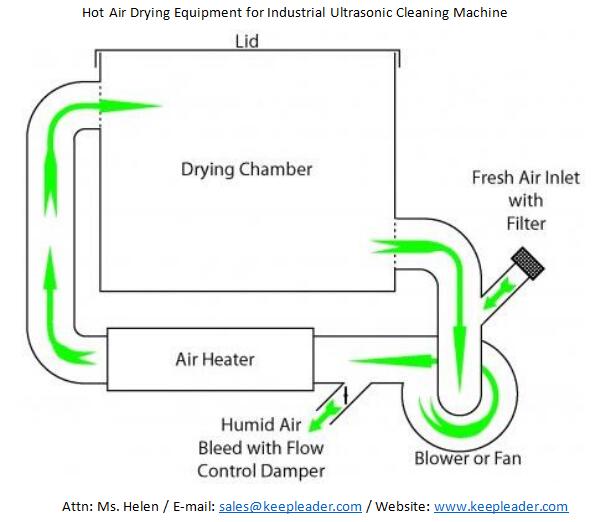

Illustration

Hot Air Drying Equipment for Industrial Ultrasonic Cleaning Machine adopts hot air circulation with high temperature resistant axial flow fan and automatic temperature control system, most hot air is circled inside the drying tank/oven/cabinet, and the drying process is hot air drying machine is high heat efficiency and energy saving

Contact Us

Hot Air Drying Equipment for Industrial Ultrasonic Cleaning Machine is reliable in industrial parts drying prior to finally assembling or surface treating, which is usually combined with your ultrasonic cleaning machine into a whole cleaning procedures, particularly for cleaning delicate parts in demanding of solution residue-free, or after water-based cleaning, the liquid is trapped in the orifices, hot air drying equipment can solve your concerns, keepleader, we construct bespoke drying system varies electric heated hot air drying, alcohol drying, high pressure cold air drying, distillation drying upon account of different mechanism assembles, of that depends on actually Working scenario and Drying,cleaning specifications, plese check or verify compatibility before purchasing, we will share our experience without percentages

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader